FREE SHIPPING on orders OVER $250

Use code SHIP4FREE at checkout

Fast Lead Times | Fast Shipping

- Pre-Terminated Fiber Optic Assemblies

- back

- In Stock Pre-Terminated

- Indoor Plenum

- Indoor / Outdoor

- Indoor Plenum Interlock Armor

- Indoor Ultra Thin Armored

- I/O Plenum Interlock Armor

- Indoor / Outdoor Ultra Thin Armored

- Outdoor SST Drop Self Supporting

- Outdoor Loose Tube (OSP)

- Outdoor Gel Filled (OSP)

- Outdoor Ultra Thin Armored (OSP)

- Outdoor Armored Direct Burial (OSP)

- Outdoor Aerial with Messenger (OSP)

- Tactical and Rugged Deployable

- back

- Multimode OM3 Tactical

- Multimode OM4 Tactical

- Singlemode Tactical

- OpticalCON Tactical

- back

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber SM - Broadcast Tactical

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber SM - Broadcast Tactical

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber SM - Broadcast Tactical

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO SM Inline Coupler

- DUO OM3 Inline Coupler

- DUO APC Inline Coupler

- OpticalCON MTP 12 Chassis Connector

- 2 Port D-Series Wall Plate

- 1 Port D-Series Wall Plate

- HMA Expanded Beam Tactical

- back

- 2 Channel/Fiber

- 4 Channel/Fiber

- Ex. Beam 2 CH/F MM OM3 Chassis Conn.

- Ex. Beam 4 CH/F MM OM3 Chassis Conn.

- 4 CH to 2 X 2 CH OM3 Ex. Beam

- 2 CH OM3 Ex. Beam to OpticalCON Duo

- 4 CH OM3 Ex. Beam to OpticalCON Quad

- 4 CH OM3 Ex. Beam to 2 x OpticalCON Duo

- Ex. Beam Color Coding Ring

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Ex. Beam 1 CH/F MM OM3 Rotary Joint

- Ex. Beam 2 CH/F MM OM3 Conn. Mod.

- Ex. Beam 4 CH/F MM OM3 Conn. Mod.

- Mil-Tac Tactical Assemblies

- Neutrik® OpticalCON®

- back

- OpticalCON DUO

- back

- 2 Fiber SM - Broadcast Tactical

- 2 Channel SM - Mil-Tac Extreme

- 2 Fiber SM Hybrid SMPTE

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber OM3 - Mil-Tac Extreme

- 2 Fiber SM - Tactical Patch Cable

- 2 Fiber OM3 - Tactical Patch Cable

- SM Duo to 2 Simplex Breakout Assembly

- OM3 Duo to 2 Simplex Breakout Assembly

- DUO Chassis Connector

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO OM3 Inline Coupler

- DUO SM Inline Coupler

- DUO APC Inline Coupler

- 1 Port D-Series Wall Plate

- OpticalCON QUAD

- back

- 4 Fiber SM - Broadcast Tactical

- 4 Fiber SM - Mil-Tac Extreme

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber OM3 - Mil-Tac Extreme

- 4 Channel SM Lite Tac Patch

- 4 Fiber OM3 - Tac Patch Cable

- SM Quad to 4 Simplex Breakout Assembly

- OM3 Quad to 4 Simplex Breakout Assembly

- QUAD Chassis Connector

- Neutrik D-Series Patch Panel

- QUAD OM3 Inline Coupler

- QUAD SM Inline Coupler

- QUAD APC Inline Coupler

- SHUTTER BUDDY

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- OpticalCON MTP

- back

- 12 Fiber SM - Broadcast Tactical

- 12 Fiber SM - Mil-Tac Extreme

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber OM3 - Mil-Tac Extreme

- 12 Channel MTP SM Lite Tac Patch

- 12 Fiber OM3 - Tac Patch Cable

- SM MTP to 12 Simplex B/O Assembly

- OM3 MTP to 12 Simplex B/O Assembly

- OpticalCON MTP 12 Chassis Connector

- Neutrik D-Series Patch Panel

- OM3 Multimode Inline Coupler

- Singlemode APC Inline Coupler

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Hybrid Fiber + Power

- MTP Trunk Cables, Fanouts, & Cassettes

- back

- Indoor MTP Trunks

- Indoor/Outdoor MTP Trunks

- Indoor Armored MTP Trunks

- In/Outdoor Armored MTP Trunks

- Outdoor Loose Tube MTP Trunks

- Outdoor Self Sup. Drop MTP Trunks

- Outdoor Micro Armored MTP Trunks

- Outdoor Armored MTP Trunks

- IP68 Weatherproof OptiTip® HMFOC

- Stock Indoor MPO Cables

- Stock In/Outdoor MTP/MPO Trunks

- Indoor MTP Fanouts

- back

- Multimode OM3 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Multimode OM4 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Singlemode 9/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- Indoor / Outdoor MTP Fanouts

- MTP OSP Loose Tube Fanout Cable

- MTP OSP Armored Fanout Cable

- Stock Indoor MPO Fanout Cables

- Cassettes and Components

- back

- OM3 Cassettes

- OM4 Cassettes

- Singlemode Cassettes

- Enclosures

- back

- Super High Density 5 panel (1U)

- Super High Density 14 panel (2U)

- Lightweight Aluminum 2 panel (1U)

- Lightweight Aluminum 3 panel (1U)

- Lightweight Aluminum 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 2 Panel (1U)

- Multilink 3 panel (1U)

- Multilink 4 panel (2U)

- Multilink 6 panel (2U)

- Multilink 12 panel (2U)

- 4 panel (1U) UHD Patch Panel

- Couplers and Adapter Panels

- MTP/MPO to LC LGX Cable Harness

- Fiber Patch Cables, Enclosures, & Couplers

- back

- Fiber Enclosures & Adapter Panels

- back

- Rack Mount Termination Boxes

- back

- Lightweight Aluminum 2 panel (1U)

- Multilink 2 Panel (1U)

- 2 panel (1U) Slide Out 16 AWG

- Lightweight Aluminum 3 panel (1U)

- 3 panel (1U) Swing Out Splice Box

- 3 panel (1U) LGX Patch Panel

- Multilink 3 panel (1U)

- 3 panel (1U) Slide Out 16 AWG

- 4 panel (1U) UHD Patch Panel

- Lightweight Aluminum 4 panel (2U)

- Multilink 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Multilink 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 12 panel (2U)

- Super High Density 5 panel (1U)

- Wall Mount Termination Boxes

- back

- QuickTreX 2 Adapter / 1-4 Fiber

- Lightweight Aluminum 1 panel

- Heavy Duty Steel 1 panel

- Multilink 1 Panel

- Multilink 1 Panel w/ Splice

- Lightweight Aluminum 2 panel

- Multilink 2 Panel

- Lightweight Aluminum 4 panel

- Multilink 4 Panel

- Multilink 4 Panel with Splice

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- Outdoor Harsh Environment

- back

- QuickTreX 1 Adapter / 1-2 Fiber

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 1 Panel Splitter/Splice Enclosure

- Multilink 2 Panel Outdoor

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- QuickTreX 12 Fiber Splice

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- Multimode OM1 Adapter Panels

- Multimode OM2/3/4 Adapter Panels

- Multimode OM5 Adapter Panels

- Singlemode Adapter Panels

- back

- QuickTreX 12 Fiber LC UPC

- QuickTreX 12 Fiber LC APC

- Multilink 12 Fiber LC UPC

- Multilink 12 Fiber LC APC

- QuickTreX 24 Fiber LC UPC

- QuickTreX 24 Fiber LC APC

- Multilink 24 Fiber LC UPC

- Multilink 24 Fiber LC APC

- QuickTreX 6 Fiber SC UPC

- QuickTreX 6 SC APC

- QuickTreX 12 Fiber SC UPC

- QuickTreX 12 Fiber SC APC

- Multilink 6 Fiber SC UPC

- Multilink 6 Fiber SC APC

- Multilink 12 SC UPC

- Multilink 12 SC APC

- MTP Adapter Panels

- Blank Adapter Panels

- Splice Trays

- Custom Fiber Optic Patch Cables

- Custom Armored Fiber Patch Cables

- Stock Tactical Fiber Patch Cables

- back

- Stock Tac SM - Duplex LC UPC - 100FT

- Stock Tac SM - Duplex LC APC - 100FT

- Stock Tac SM - Duplex SC APC - 100FT

- Stock Tac SM - Duplex SC UPC - 100FT

- Stock Tac SM - Simplex LC UPC - 100FT

- Stock Tac SM - Simplex SC UPC - 100FT

- Stock Tac SM - Simplex SC APC - 100FT

- Stock Tac SM - Simplex LC APC - 100FT

- Stock Duplex Fiber Patch Cables

- Stock Uniboot Fiber Patch Cables

- Stock Simplex Fiber Patch Cables

- Fiber Optic Couplers & Attenuators

- back

- Multimode OM1 62.5/125

- back

- LC Simplex w/ Flange

- LC Duplex w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Simplex w/ Flange and Hinged Door

- LC Quad w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM3/4 50/125

- back

- LC Duplex w/ Flange

- LC Quad w/o Flange

- LC Quad w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- MPO Coupler - MM OM3 / OM4 Aqua

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM5 50/125

- Singlemode

- back

- LC UPC Simplex w/o Flange

- LC APC Simplex w/o Flange

- LC UPC Duplex w/ Flange

- LC APC Duplex w/ Flange

- LC UPC Quad w/o Flange

- LC APC Quad w/o Flange

- SC UPC Simplex w/ Flange

- SC UPC Simplex w/o Flange

- SC UPC Simplex w/ Flange and Hinged Door

- SC APC Simplex w/ Flange

- SC APC Simplex w/o Flange

- SC APC Simplex w/ Flange and Hinged Door

- SC UPC Duplex w/ Flange

- SC APC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Simplex - Universal MM/SM w/o Flange

- Keystone Couplers & Accessories

- back

- LC Duplex MM OM1 - Ivory

- LC Duplex MM OM3 / 4 - Aqua

- LC Duplex MM OM5 - Lime Green

- LC UPC Duplex SM - Blue

- LC Duplex SM APC - Green

- SC Simplex MM OM1 - Beige

- SC Simplex MM OM3 / 4 - Aqua

- SC UPC Simplex SM - Blue

- SC APC Simplex SM - Green

- MTP Singlemode

- MTP Multimode OM3/4

- Gloss Finish Keystone Wallplates

- Easy Wallplate Bracket

- 12 Port - 1U

- 6 Port LGX Blank Keystone Adapter Panel

- MTP / MPO Couplers

- Optical Attenuators

- Fiber Optic Splitters

- Mode Conditioning Fiber Cables

- Bulk Fiber Optic Cable, Testing, & Cleaning

- back

- Unterminated Fiber Optic Cable

- Fiber Optic Pigtail Kits

- back

- OM1 62.5/125 Multimode

- OM3 50/125 Multimode

- OM4 50/125 Multimode

- OM5 50/125 Multimode

- Singlemode

- back

- 1 meter LC 6 Fiber

- 3 meter LC 6 Fiber

- 3 meter SC 6 Fiber

- 1 meter ST 6 Fiber

- 3 meter ST 6 Fiber

- 1 meter LC 12 Fiber

- 3 meter LC 12 Fiber

- 3 meter LC APC

- 3 meter LC 12 Fiber Ribbon

- 3 meter SC APC 12 Fiber

- 3 meter SC 12 Fiber

- 3 meter SC UPC 12 Fiber Ribbon

- 1 meter ST 12 Fiber

- 3 meter ST 12 Fiber

- 2 meter LC 1 Fiber

- 2 meter SC 1 Fiber

- Fiber Optic Splice Trays & Boxes

- back

- Fiber Optic Splice Enclosures

- back

- Multilink 2 Panel Outdoor

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 480 Splice Dome Enclosure

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 1 Panel Splitter/Splice Enclosure

- Multilink 1 Panel w/ Splice

- Multilink 4 Panel with Splice

- Lightweight Aluminum 1 panel

- 3 panel (1U) Swing Out Splice Box

- QuickTreX 12 Fiber Splice

- Fiber Optic Splice Trays

- Fiber Optic Supplies & Tools

- Fiber Optic Cleaning Products

- Fiber Optic Test Instruments

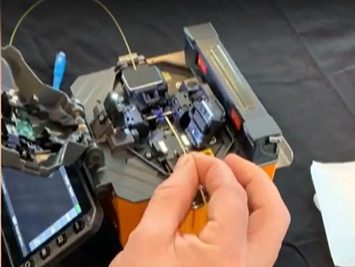

- Fusion Splicers and Accessories

- Fiber Optic Loopback Testers

- Fiber Optic Mounting Hardware

- Fiber Optic Reference Cable Kits

- Ethernet Patch Cables, Bulk Cable, & Accs.

- back

- Ethernet Patch Cables

- back

- Tactical & Rugged Deployable

- back

- Cat 5E Shielded - Custom Length

- Stock 40FT Cat 5E Shielded

- Cat 6A Shielded - Custom Length

- Stock 30FT Cat 6A Shielded

- RJ45 etherCON Coupler

- RJ45 etherCON Coupler w/ Sealing Kit

- RJ45 Cat 6A etherCON Coupler - Black

- Cat 6A etherCON Coupler - Nickel

- Neutrik D-Series Patch Panel

- Cat 6 Outdoor Inline

- Cat 6A Outdoor Panel Mount w/Cap

- Cat 6A Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- Cat 5E Custom Made in the USA

- Cat 5E Stock

- Cat 6E Custom Made in the USA

- Cat 6 Stock

- Cat 6A Custom Made in the USA

- Cat 6A Stock

- Cat 6A Stock Outdoor Armored

- Stock Cat 6A Shielded Tactical

- Outdoor Custom Made in the USA

- Cat 6 Outdoor

- Cat 8 Custom Made in the USA

- Cat 7 Stock

- Cat 8 Stock

- 110 Cat 5 Custom Patch Cables

- Custom Cable Bundles

- Bulk Ethernet Cable

- back

- Cat 5e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, Riser (CMR), Solid, 1000 ft

- 24AWG Solid Riser , 1000 ft

- Plenum Rated Solid 1000FT USA Made

- Solid Plenum 1000FT

- 24AWG Solid Plenum, 1000 ft

- Direct Bury, CMX, Solid, 1000 ft

- 24 AWG Direct Burial Solid, 1000 ft

- 24 AWG Outdoor DB 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 5E Shielded

- Cat 6 / 6e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, 28 AWG Stranded, 1000 ft

- PVC Riser (CMR), Solid, 1000 ft

- 23AWG Solid Riser (CMR), 1000 ft

- Plenum (CMP), Solid, 1000 ft

- 23AWG Solid Plenum (CMP), 1000 ft

- Outdoor DB Solid 1000FT USA Made

- Direct Burial, CMX, Solid, 1000 ft

- Outdoor w/Messenger 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 6 / 6E Shielded Bulk Cable

- Cat 6A Unshielded

- Cat 6A Shielded

- Cat 7A Shielded

- Cat 8 Shielded

- Data & Voice Connectors

- back

- Keystone Jacks

- back

- Cat 5E - 90° Punch Down

- Cat 5E - 180°Punch Down

- Cat 6 - 90° Punch Down

- Cat 6 - 180° Punch Down

- Cat 6 Shielded 90° Punch Down

- Cat 6A - 90° Punch Down

- Cat 6A Shielded 90 Degree

- Cat 6A Shielded -180° Toolless

- Cat 8 Shielded - 90° Toolless

- Cat 8 Shielded - 90° Toolless w/Door

- RJ-11/12 Voice - 90° Punch Down

- Keystone Couplers

- Modular Plugs

- back

- Cat 5E UTP - 100 pcs USA Made

- Cat 6/6E UTP - 100 pcs USA Made

- Cat 5E/6E STP - 50 pcs USA Made

- Cat 5E/6E STP - 10 pcs USA Made

- Cat 6A STP - 50 pcs USA Made

- Cat 6A STP - 10 pcs USA Made

- Cat 8 STP - 10 pcs

- Cat 8 STP - 25 pcs

- Cat 8 STP Toolless

- Cat 6A UTP - 100 pcs

- Cat6 UTP Feed Through - 100 pcs

- Cat 6 STP Feed Through - 100 pcs

- Strain Relief Boots

- Wallplates and Surface Mount Boxes

- Splitters

- Coaxial F Connectors

- Ethernet Patch Panels

- Datacom Tools and Testers

- back

- Data & Voice Tools

- back

- PRO RJ-45 Crimper

- PRO Large OD Crimper

- Hex Crimper

- Economy RJ-45 Crimper

- PRO 110 Impact Termination Tool

- 110 Replacement Blade

- 66 Replacement Blade

- EZ RJ45 Keystone Jack Crimper

- Economy Termination Tool

- Wire and Kevlar Scissors

- Large OD Cable Stripper & Cutter

- UTP & STP Cable Stripper

- Electrical Wire Stipper

- Coaxial Cable Cutter

- Conductor Separator & Straightener

- QuickTreX Premium Adjustable Hat

- Test Equipment

- Cable Installation

- Coaxial CATV Tools

- Hand Tools

- Cable Reels

- Bulk Coaxial, Audio, and Power Cable

- back

- Co-ax RG-6 Shielded Bulk Cable

- back

- Dual Shield CCS Riser, 1000 ft WT

- Quad Shield CCS Riser, 500 ft BK

- Quad Shield CCS Riser, 1000 ft BK

- Quad Shield CCS Plenum, 1000 ft WT

- Quad Shield Solid Copper Plenum, 1000

- Dual Shield Direct Burial CCS, 1000 ft BK

- Quad Shield Direct Burial CCS, 1000 ft BK

- RG6 F Male Compression 10 Pack

- Cable Reel Deployment Caddy

- Composite Cable & Cable Bundles

- Power Cable Bulk

- Thermostat Bulk Cable

- back

- 18/2 Riser Rated, Solid Copper PVC, 500 ft

- 18/3 Riser Rated, Solid Copper PVC, 500 ft

- 18/4 Riser Rated, Solid Copper PVC, 500 ft

- 18/5 Riser Rated, Solid Copper PVC, 500 ft

- 18/6 Riser Rated, Solid Copper PVC, 500 ft

- 18/8 Riser Rated, Solid Copper PVC, 500 ft

- 20/2 Riser Rated, Solid Copper PVC, 500 ft

- 20/5 Riser Rated, Solid Copper PVC, 500 ft

- 20/8 Riser Rated, Solid Copper PVC, 500 ft

- Cable Reel Deployment Caddy

- Audio Cable Bulk

- IT Technician Tool Kits and Cases

- Cable Mounting Hardware

- HDMI Cables

- Power Cords and Supplies

- Harsh Environment Cables, FTTA, RF, & IP68

- back

- OptiTip, OptiTap, HMA, & FTTA

- RF Cable Assemblies

- RF Connectors & Adapters

- back

- RF Connectors

- back

- Mini-UHF Male Crimp

- Mini-UHF Male Crimp RG-58/U

- UHF Male Solder

- UHF Male Crimp

- M Male Crimp

- N Male Crimp 50 ohm

- N Male Crimp G,G,T, 50 ohm

- N Male Crimp For Cable Group X S,G,T

- N Male Crimp RG-142/U & RG-55/U

- N Male Crimp for Cable Group B N,G,T

- SMA Male Crimp

- SMA Male Crimp RG-8/X

- SMA Male Crimp for Cable Group B N,G,T

- BNC Male Crimp RG58/U

- TNC Male Crimp RG-58/U

- TNC Male Crimp RG-8X

- RF Adapters

- Harsh Env. Fiber Optic Assemblies

- Toolkits, Cases & Enclosures

- back

- Termination Boxes

- back

- Multilink 2 Panel Outdoor

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 1 Panel Splitter/Splice Enclosure

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- Network IT Toolkits

- Network IT Tool Cases

- Ethernet Patch Cables & Bulk Cable

- back

- Copper Cables and Assemblies

- Bulk Outdoor Copper Cable

- Outdoor Patch Cables

- Outdoor Accessories

- back

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Cat 6 Shielded Outdoor Panel Mount

- Cat 6 Shielded Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- 1 Gang Outdoor Wallplate

- Water-Resistant 1 Gang

- 1 Port (1 Gang) Stainless Steel Keystone Wall Plate for Mounting RJ45 Keystone Connectors and Couplers

- Network Switches, SFPs, Converters, & Racks

- back

- Network Switches

- back

- Unmanaged Gigabit

- Managed Gigabit

- Unmanaged Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 4xRJ45,1xRJ,1xSFP

- QuickTreX 12 Port GIG w/ 8xRJ45,2xRJUL,2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 2xSFP

- QuickTreX 48 Port GIG w/ 48xRJ45 & 2xSFP

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 16 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 4 Port Gigabit

- Managed Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 8xRJ45 & 2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 4xSFP/RJ45

- QuickTreX 36 Port 10G UL w/ 24xRJ45, 8xSFP, 4xSFP+

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port G w/ 4 x GIG SFP Ports + PoE Inj

- 24 Port Gigabit w/ 4 x 10Gigabit SFP Ports

- 24 Port Gigabit w/ 2 SFP Ports (Full Power)

- 24 Port Gigabit w/ 4 SFP+ Ports (Full Power)

- Unmanaged Industrial Switches

- Managed Industrial Switches

- Unmanaged Industrial PoE Switches

- back

- QuickTreX 6 Port GIG w/ 4xRJ45 & 2xSFP

- QuickTreX 10 Port GIG w/ 8xRJ45 & 2xSFP

- 4 Port Gigabit POE+ w/ 2 SFP Ports

- 4x10/100M TX PSE and 1x1000M SC MM

- 4x10/100M TX PSE + 1x10/100M

- 5 x RJ45 10/100/100BaseTX

- 5 x RJ45 1000Bast w/ 4 x Gig 30W PSE

- 8 x RJ45 10/100/1000m w/ v Boost

- 8 Port Gigabit POE+ w/ 2 SFP Ports

- 8 x Gig TX 30W PSE + 2 x 1000M TX/SFP w/ v Boost

- Managed Industrial PoE Switches

- Industrial Power Supplies

- SFP / QSFP Modules

- back

- Multimode SFP Modules

- Singlemode SFP Modules

- back

- 1.25 GIG - 2km at 1310nm by QuickTreX

- 10 GIG - 10km at 1310nm by QuickTreX

- 1F/BiDi Kit 1.25 GIG - 20km by QuickTreX

- 1.25 GIG - 20km at 1310nm by Unicom

- 1.25 GIG - 40km at 1310nm by Unicom

- 1.25 GIG - 80km at 1310nm by Unicom

- 1.25 GIG - 100km at 1310nm by Unicom

- 1.25 GIG - 120km at 1310nm by Unicom

- 1.25 GIG - 160km at 1310nm by Unicom

- 1.25 GIG - 180km at 1310nm by Unicom

- 10 GIG - 10km at 1310nm by Unicom

- 10 GIG - 40km at 1550nm by Unicom

- 10 GIG - 80km at 1550nm by Unicom

- 10 GIG - 100km at 1550nm by Unicom

- 10 GIG - 10km at 1310nm Cisco Compatible

- 1.25 GIG - 10km at 1310nm by Signamax

- Industrial SFP Modules

- back

- MM 1.25 GIG - 500 m / 850nm by QuickTreX

- SM 1.25 GIG - 20 km / 1310nm by QuickTreX

- MM 10 GIG - 300m / 850nm by QuickTreX

- SM 10 GIG - 10 km / 1310nm by QuickTreX

- MM GIG - 550m / 850nm by Signamax

- MM GIG - 2km / 1310nm by Signamax

- SM GIG - 10km / 1310nm by Signamax

- SM GIG - 40km / 1310nm by Signamax

- SM GIG - 40km / 1550nm by Signamax

- SM GIG - 80km / 1550nm by Signamax

- SM GIG - 110km / 1550nm by Signamax

- SM BiDI GIG - 10km 1310TX/1550RX

- SM BiDI GIG - 10km 1550TX/1310RX

- QSFP Modules

- Media Converters

- Network Racks and Cabinets

- back

- Free Standing Racks

- Open Frame Wall Rack

- back

- QuickTreX 16U (19"W x 18"D)

- Kendall Howard 8U (Adjustable W x 18"D)

- Kendall Howard 12U (Adjustable W x 18"D)

- Kendall Howard 12U Swing-Out

- Kendall Howard 18U Swing-Out

- Kendall Howard 12U Side Load

- Kendall Howard 12U (19"W x 12"D)

- Kendall Howard 16U (19"W x 12"D)

- Kendall Howard 12U (19"W x 18"D)

- Kendall Howard 16U (19"W x 18"D)

- Kendall Howard 2U Vertical w/ Tapped Rails

- Kendall Howard 4U Vertical w/ Tapped Rails

- Kendall Howard 2U Vertical

- Kendall Howard 4U Vertical

- Wall Mount Network Cabinets

- back

- QuickTreX 4U Swing-Out Hinged

- QuickTreX 4U Fixed

- QuickTreX 6U Swing-Out Hinged

- QuickTreX 6U Fixed

- QuickTreX 9U Swing-Out Hinged

- QuickTreX 9U Fixed

- QuickTreX 12U Fixed

- 6U Wall Mount - Glass Door

- 6U Wall Mount - Solid Door

- 6U Wall Mount - Vented Door

- 6U Swing Out Wall Mount - Glass Door

- 6U Swing Out Wall Mount - Solid Door

- 6U Swing Out Wall Mount - Vented Door

- 9U Wall Mount - Glass Door

- 9U Wall Mount - Vented Door

- 9U Wall Mount - Solid Door

- Network Rack & Cabinet Shelves

- Hardware, Fans, and Accessories

- Rack Mount Cable Management Panels

- Wireless Access Points

- Cable Wraps, Straps, and Ties

- back

- Pre-Cut Hook & Loop Velcro Cable Ties

- back

- 6" x 1/2" Velcro Cable Ties - 25 pcs

- 6" x 1/2" Velcro Cable Ties - 100 pcs

- 6" x 1/2" Velcro Cable Ties - 1200 pcs

- 8" x 1/2" Velcro Cable Ties - 25 pcs

- 8" x 1/2" Velcro Cable Ties - 100 pcs

- 8" x 1/2" Velcro Cable Ties - 900 pcs

- 12" x 1/2" Velcro Cable Ties - 25 pcs

- 12" x 1/2" Velcro Cable Ties - 100 pcs

- 12" x 1/2" Velcro Cable Ties - 600 pcs

- 18" x 1/2" Velcro Cable Ties - 25 pcs

- 18" x 1/2" Velcro Cable Ties - 100 pcs

- 18" x 1/2" Velcro Cable Ties - 400 pcs

- Bulk Roll Velcro Cable Strap

- Wall Mount Velcro Cable Straps

- Fire Retardant Hook & Loop Cable Ties

- back

- 8" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 8" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 8" x 1/2" Velcro Ties - 900 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 600 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 400 pcs

- 75 Ft x 1/2" Roll Velcro Cable Wrap Strap

- Economy Velcro Cable Ties

- Cable Bundle Socks

- Clip-On Velcro Cable Carrier

- TV & LCD Screen Mounts

- back

- Wall Mount TV/LCD Screen Mounts

- back

- 13" - 27" Screen w/ 10.4" Arm

- 13" - 42" Screen w/ 10.7" Arm

- 10" - 42" Screen w/ 7.5" Arm

- 10" - 42" Screen w/ 2.9" Arm

- 13" - 42" Screen w/ 14.3" Arm

- 26" - 47" Screen w/ 22.8" Arm

- 32" - 70" Screen w/ 18.4" Arm

- 37" - 80" Screen w/ 18.4" Arm

- 32" - 55" Screen

- 37" - 70" Screen

- 37" - 80" Screen

- XL 60" - 100" Screen

- Slim Fixed 32" - 55" Screen

- Fixed 32" - 55" Screen

- Fixed 37" - 70" Screen

- Ceiling Mount TV/LCD Screen Mounts

- NPT Pipe TV Ceiling Mounts

- back

- 1.5" NPT Pipe Mount 32" - 55" Screen

- 1.5" NPT Pipe Mount 23" - 42" Screen

- 1.5" Double Sided NPT Mount 32"-55"

- 1.5" NPT Mount 37"-70"

- Flat Ceiling Plate for 1.5" NPT Pipe

- Angled Ceiling Plate for 1.5" NPT Pipe

- 1.5" NPT x 34.4 Long NPT Pipe

- Adjustable NPT Pipe 1.5"D x 8.66-14.57"L

- 1.5" NPT Pipe Coupler

Login

Pre -Terminated Fiber Optic Cable Assemblies

OUR ONE-OF-A-KIND QUICKTREX PRE-TERMINATED FIBER OPTIC CABLE ASSEMBLIES ARE CUSTOM MADE TO ORDER IN THE USA AND HAVE A LONG REPUTATION OF 25+ YEARS FOR PREMIUM QUALITY AND RELIABILITY THAT CANNOT BE BEAT. ALL OF OUR PRE-TERMINATED FIBER OPTIC CABLE ASSEMBLIES, UNLESS OTHERWISE STATED; INCLUDE CORNING GLASS AND PREMIUM COMPONENTS. WE HAVE A STRICT QUALITY CONTROL MANUFACTURING PROCESS AND ARE ISO 9001 CERTIFIED. OUR FINELY TUNED MANUFACTURING AND ORDERING PROCESS PROMOTES LIGHTING FAST PRODUCTION TIMES SO YOU HAVE YOUR PRE-TERMINATED FIBER OPTIC ASSEMBLY IN HAND FAST AND READY TO PULL. WE OFFER OUR PRE-TERMINATED FIBER OPTIC CABLE ASSEMBLIES IN ANY FIBER TYPE, JACKET TYPE, CONNECTOR TYPE, AT ANY LENGTH. QUICKLY AND CONCISELY CHOOSE THE EXACT ASSEMBLY YOU’RE LOOKING FOR BELOW. MATCH YOUR JACKET TYPE ON THE LEFT SIDE OF THE PAGE TO THE FIBER TYPES AT THE TOP AND THEN CHOOSE YOUR STRAND COUNT TO GET TO THE PRODUCT PAGE. YOU CAN THEN CHOOSE YOUR EXACT LENGTH, CONNECTOR TYPE, AND WHETHER OR NOT YOU WANT PULLING EYES ON ONE END OR BOTH. AS SOON AS YOU PLACE YOUR ORDER, YOU'LL RECEIVE AN ORDER CONFIRMATION, A SHIP DATE WITHIN 24 BUSINESS HOURS, AND THEN TRACKING ONCE YOUR PRE-TERMINATED FIBER OPTIC ASSEMBLY SHIPS OUT.

Show MoreBuild your Custom Pre-Terminated Assembly:

Click on any jacket type or strand count below to build your custom preterminated fiber optic assembly.

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM3

Multimode OM4

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM3

Multimode OM4

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM2

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM2

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM2

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM2

Multimode OM4

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

Singlemode

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

Singlemode

|

||||||

|

Jacket Type

|

Multimode OM1

|

Multimode OM2

|

10G Multimode OM3

|

Multimode OM4

|

Multimode OM5

|

Singlemode

|

|---|---|---|---|---|---|---|

|

Jacket Type

Multimode OM1

Multimode OM2

Multimode OM3

Multimode OM4

Multimode OM5

|

||||||

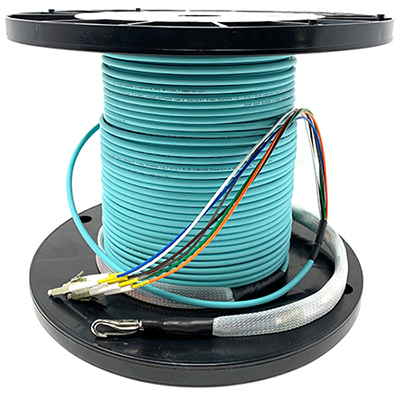

Our pre-terminated Fiber Optic Cables offer a plug and play custom fiber solution for seamless installation in electrical conduits or within walls for both residential and commercial settings. They ensure the efficient delivery of audio, video, data, fiber internet, smart controls, and support HDMI in 4k and 8k. Additionally, hybrid combo options with bundled electric wires are also available.

All our Pre Terminated Fiber Optic Assemblies are custom made in the USA at the time of your order, are made to your exact specifications, and come with test results.

These Pre-terminated assemblies can be ordered in either indoor (plenum), indoor/outdoor, tactical, outdoor variations in non-armored or armored.

Strand counts from 2, 4, 6, 12 , 24 and all the way up to 288 strand fiber counts in the fiber core of Multimode OM1, OM2, OM3 OM4, OM5 or Singlemode.

A pulling eye is recommended and can be factory installed. The pulling eye (and associated cable netting) will protect the preterminated ends during the pull.

This product is a great time and money saver for those who need to install fiber optic cabling.

Advantages of Pre-Terminated Assemblies for Installers

Pre-terminated fiber optic assemblies offer a myriad of advantages for installers in various settings. Firstly, these assemblies streamline the installation process, significantly reducing the time and effort required for setup. With connectors already attached and tested, installers can avoid the intricacies of field termination, ensuring a quicker and more efficient deployment. This time-saving aspect not only accelerates project completion but also minimizes the potential for errors during field terminations, enhancing overall reliability.

In addition to time efficiency, pre-terminated fiber optic assemblies contribute to enhanced performance and reliability. The factory-controlled termination process ensures precision and consistency in connector termination, resulting in optimal signal integrity. This precision is particularly crucial in high-speed data transmission applications, such as 4k and 8k video, where signal quality is paramount. By relying on pre-terminated assemblies, installers can be confident in the reliability of their installations, knowing that each connection meets stringent industry standards.

Furthermore, pre-terminated fiber optic assemblies offer flexibility in deployment scenarios. Their compatibility with various environments, including residential and commercial spaces, allows for versatile applications. Whether it's pulling through electrical conduits or routing within walls, these assemblies adapt seamlessly to diverse installation requirements. The availability of hybrid options, incorporating bundled electric wires, further enhances versatility, addressing the evolving needs of modern installations that may involve a combination of audio, video, data, and power requirements.

Overview

LANshack.com has been specializing in custom pre-terminated fiber optic cable assemblies for over 25 years. We offer a wide variety of options including jacket types, fiber types, and connector types to customize the assembly to your exact specifications. All assemblies are made in the USA by trained technicians and come with test results. Need something you don't see here? Contact us, our knowledgeable team will help you find all the custom jackets and connectors for pre-terminated fiber optic cables that you need!

Indoor

Indoor fiber optic cable is a tight buffer design with internal components consisting of a non-metallic strengthen member, the tight buffer optical fiber, the Kevlar strength member, and the outer cable jacket. The trend is to use LSZH or other RoHS compliant PVC materials to make the cable jacket; this will help protect the environment and the health of the end-users.

Indoor/outdoor

Indoor/outdoor fiber-optic cable is designed to meet both the rigorous environment of the outdoors and can be routed indoors, where flame rating requirements also apply. Indoor-outdoor cable eliminates the need for a "transition splice" to an indoor-rated cable when routing an outdoor cable into the building.

Interlocking armored cables are standard distribution cables inside a spirally-wrapped aluminum interlocking armor with a heavy-duty outer jacket. This combination provides superior crush resistance and is also useful for warehouses or attic areas where the presence of rodent chew hazards may exist.

Ultra-thin micro armor

Our Ultra Thin Armored Pre-Terminated Fiber Optic Cable Assemblies utilize Micro Armor Fiber™. A revolutionary designed fiber optic cable that provides a perfect solution for your fiber optic installs and usage. Instead of a traditional interlocking armor, it utilizes stainless steel coil technology. This allows for the cable to remain highly flexible while also being crush and rodent resistant. Micro Armor Fiber™ features the smallest outer diameter compared to conventional armored fiber optic cable in size and flexibility. Its lightweight and great flexibility make pulling and installation faster and easier. These assemblies are typically up to 65 percent smaller in diameter and 75 percent lighter than the traditional aluminum interlocking armor cable. These assemblies provide a perfect combination of strong armor and maximum bend radius. Choosing an armored jacket helps save time and money in indoor applications where innerduct or conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor distribution cable, it outweighs its overall price when compared to the cost of purchasing innerduct/conduit, indoor fiber, and installation for both.

Outdoor

Outdoor fiber is suitable for indoor and outdoor use, so there is no 50-foot fire code requirement traditionally found with outdoor (OSP) cable. This indoor/outdoor armored cable has a water-blocking aramid yarn strength member surrounding the fiber optic strands and a UV resistant outer jacket making it a very versatile and perfect choice for a large variety of installations.

Our pre-terminated fiber optic cable assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, multi-floor deployment where select fibers are used at each floor, or intra-building backbones. Our indoor/outdoor plenum-rated jacket assemblies are rated for all indoor installations, including plenum-rated spaces. A cable rated for plenum installation will have low-smoke characteristics as defined by the NFPA (National Fire Protection Agency).

Direct Burial

Choosing a direct burial-rated jacket helps save time and money in outdoor applications where conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor/outdoor distribution cable that needs to be run inside the conduit, it outweighs its overall price when compared to the cost of purchasing the conduit and then having to pull the cable through it. This outdoor (OSP) armored cable has a heavy-duty polyethylene (PE) UV and waterproof jacket and water blocking aramid yarn strength members surrounding the fiber optic strands.

Our pre-terminated fiber optic cable assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. It's perfect for trenches or underground installation where rodent chew damage is a concern, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. The drawback of outdoor (OSP) cable is that it is mandated at a maximum of 50 feet run indoors due to fire-code regulations.

Armored Direct Burial

Our Corning Altos® Outdoor Armored Direct Burial (OSPDB) Pre-Terminated Fiber Optic Cable Assemblies are rated for almost all outdoor applications. These assemblies are the most durable and rugged assemblies we offer for permanent installation. They are designed for installation directly buried in trenches and underground installation where rodent chew damage is a concern, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. This jacket design also offers superior crush resistance. Our outdoor armored pre-terminated fiber optic cable assemblies are perfect for campus backbones, headend termination to a fiber backbone, and intra-building backbones. They are also designed for a variety of voice, data, video, and image applications. If installing in conduit we recommend using at least a 3" diameter conduit to accommodate for the assembly breakout.

Choosing a direct burial-rated jacket helps save time and money in outdoor applications where conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor/outdoor distribution cable that needs to be run inside conduit, it outweighs its overall price when compared to the cost of purchasing conduit and then the labor involved having to pull the cable through it. This outdoor (OSPDB) armored cable has a heavy-duty polyethylene (PE) UV and waterproof jacket, corrugated steel tubing, and water blocking swellable tape surrounding the fiber optic strands. Polyethylene (PE) OSP cable is restricted to a 50 foot run indoors due to fire-code restrictions.

Loose Tube

Loose Tube Cables are composed of several fibers together inside a small plastic tube, which is in turn wound around a central strength member and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside plant trunking applications, as it can be made with loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead, or buried directly into the ground. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage.

Gel-Filled

Gel-filled pre-terminated fiber-optic cables ensure water or moisture does not damage a fiber optic cable because the tubes contain water blocking agents. These tubes either include a water blocking gel or a water-swellable material to ensure the optical fibers are not compromised. Gel-filled tubes prevent the ingress of water by filling the negative space within the tube, essentially blocking the entrance and any flow of water. The gel also provides another layer of protection for the optical fibers and, because they are free-floating, causes less tension on the fibers. The main disadvantage of gel-filled loose tube fiber optic cable is that you have to clean the gel from the fibers which slow down the installation process and can be a mess for installers.

Flat Drop

Flat drop cable, with a flat out-looking, usually consists of a polyethylene jacket, fiber counts up to 12 or more, and two dielectric strength members to give high crush resistance. Flat drop fiber optic cable allows versatility for network edge installations. The dual radial strength members allow for aerial self-support lengths of up to 290 feet in light loading conditions. This cable also has the crush resistance properties to be directly buried. For such cases, flat drop cable may be available with a tone wire for ease of locating.

Aerial with Messenger

Our Outdoor (OSP) Aerial with Messenger Pre-Terminated Fiber Optic Cable Assemblies are rated for almost all outdoor applications. These assemblies are perfect for outdoor aerial installations along utility poles without the need for cable lashing. It comes in a figure 8 configuration, consisting of the messenger, the webbing, and the fiber optic cable. There are several advantages of the figure 8 messenger configuration, mainly that it reduces cost by eliminating the need to purchase a separate messenger wire and lashing wire and then having to attach the assembly to the messenger wire. With our aerial with messenger assemblies, there is only one installation job, which also reduces labor costs.

This cable includes a very heavy-duty polyethylene jacket and can withstand the harshest outdoor elements including. Our outdoor (OSP) pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. Note: Polyethylene (PE) OSP cable is restricted to 50 feet run indoors due to fire-code restrictions.

Rugged Tactical

QuickTreX® Tactical & Rugged Pre-Terminated Fiber Optic Cable Assemblies are designed to withstand the harshest of environments. They are excellent for setting up temporary networks needed for test result gathering, demonstrations, concerts, festivals, or any other outdoor event. They are also excellent for a backup backbone to your critical network. Our Tactical and Rugged Assemblies come on a heavy-duty Schill deployment reel and are designed to be quickly deployed and retrieved. These Schill reels include a door that houses the connectors for safe and secure storage while not in use. These assemblies include military-grade connectors with water-resistant caps for when not in use. Our Tactical & Rugged Fiber Assemblies include a cover sleeve and wire mesh handle on the pull end of the assembly which allows for fast deployment while also protecting the connectors from damage.

Tactical OpticalCON

Our QuickTrex opticalCON DUO® fiber optic assemblies harness the power of the Neutrik® brand tactical connector, with tactical grade fiber to provide a superior rugged product. QuickTreX® Tactical & Rugged Pre-Terminated Fiber Optic Assemblies are designed to withstand the harshest of environments. This assembly is military-approved and is ideal for audio and broadcast networks.

The opticalCON DUO cable connector houses a standard optical LC-Duplex connector in a ruggedized and durable all-metal housing. A spring-loaded push-pull locking mechanism provides superior protection for the connectors, and the fiber provides excellent cable retention utilizing aramid yarn. An automatically operated sealing cover protects the connectors from all contaminants like dirt and dust.

Our Tactical and Rugged Assemblies can optionally be installed on a heavy-duty Schill deployment reel, designed for quick deployment and retrieval. These Schill reels include a door that houses the connectors for safe and secure storage while not in use. Our Tactical & Rugged Fiber Assemblies include an optional cover sleeve and wire mesh handle on the pull end of the assembly which allows for fast deployment while also protecting the connectors from damage. This assembly is made in the USA by skilled technicians under controlled conditions and comes to you fully tested and ready for immediate use. The test results are placed on the inside of the door.

Hybrid

Hybrid Copper-Fiber Cables allow end-users to take advantage of DC power and fiber in one cable to safely deliver low-voltage power and data over long distances to remote locations where standard power is unavailable or too costly to install. Hybrid cable technology offers installation and labor savings by requiring just a single cable pull. Various cable constructions offer unlimited application flexibility.

What Fiber Stand Counts Do We Offer?

When working with fiber, an important thing to keep in mind is that with standard equipment, you will need two fiber strands to make a connection: one transmit signal (Tx), and one receive signal (Rx). So, when you purchase a 2 Strand Assembly, you will have one fiber pair, and will be able to complete one connection. When you purchase a 4 Strand Assembly, you will have two fiber pairs, and two connections, and with a 6 strand assembly, three fiber pairs, and three connections, and so on. We offer some assemblies in strand counts up to 144, which would provide 72 fiber connections. For higher strand counts we also offer

Fiber Connector Types We Offer

LC

The LC fiber optic connector is a small form factor connector that snaps in. It includes a 1.25 mm ceramic ferrule. The LC connector is very popular and offers great performance for high density or compact areas. Most SFP modules accept LC connectors.

SC

The SC fiber optic connector is a snap-in connector that latches with a push-pull motion. It includes a 2.5 mm ceramic ferrule. This connector and is commonly used because it provides excellent performance. Many media converters accept SC connectors.

ST

The ST fiber optic connector is typically metallic and utilizes a spring-loaded twist and lock style connection with a bayonet mount. It includes a 2.5 mm ferrule that is usually ceramic but can also be polymer. Many media converters accept ST connectors.

FC

The FC fiber optic connector is a metallic connector that is threaded and screws on. It includes a 2.5 mm ceramic ferrule. It’s been mostly phased out but is still sometimes used is applications where vibration and movement can become an issue.

Connector Polish Options

In Singlemode fiber, our ST and MTRJ connectors are available in an upgraded UPC polish option, and our LC, SC, and FC are available in both UPC and APC polish. APC connectors feature a fiber end face that is polished at an 8-degree angle, while UPC connectors have a slight curvature for better core alignment. The different polish options help with improving return loss, which is a measurement of reflected light.

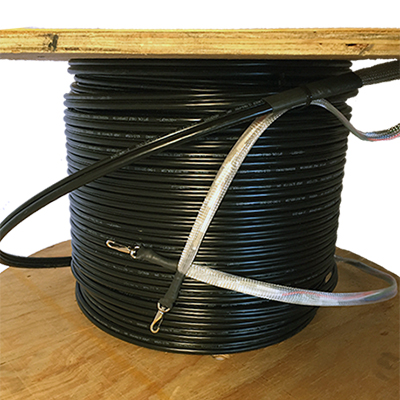

Pulling Eyes

A pulling eye is designed to be attached to a pull string that runs the full length of your conduit. Your assembly is then pulled through the conduit via the pull string. It can also be used to pull your assembly through duct work, in wall cavities, or other areas where routing needs to take place. Our pulling eyes include a heavy-duty swivel hook to prevent the cable from twisting during the pull. The metal pull hook is attached to a designated pull string inside of your assembly usually consisting of Kevlar so that you are not pulling on the fiber strands themselves. The pulling eye includes heat shrink tubing that covers the back side of the pull hook, and the pull basket that contains your fiber optic connectors. The pull basket is constructed with super strong polyethylene mesh that tightens itself around the strands and connectors keeping them securely in place during install. The connectors are also staggered inside of the pull basket for less bulk, and each connector is individually plastic wrapped to prevent contamination by pulling lubricants and other debris. Our pulling eyes are always recommended as they make your pull much easier while providing further protection of your connectors. We always recommend pulling eyes on both ends, even if you’re only pulling one end of the assembly. This helps protect the back side of your assembly’s connectors and prevent damage. The pull hook can be secured on the back end to prevent twisting and flapping of your connectors during install.

Pre-Terminated Fiber Cable vs. Field-Terminated Fiber Cable

When comparing pre-terminated fiber optic cable to field-terminated fiber cable, it is essential to understand the advantages and considerations associated with each option.

Pre-terminated fiber cable assemblies come with factory-installed connectors, making them ready for immediate deployment upon arrival. This minimizes installation time and reduces the need for specialized labor, ensuring a quicker and more straightforward installation process.

The pre-terminated fiber optic assemblies are precisely manufactured and tested in controlled environments, ensuring high-quality connections and optimal performance.

On the other hand, field-terminated fiber cables require connectors to be installed on-site during the installation process. While this option offers more flexibility in terms of cable length customization, it typically demands more time and skilled labor for termination.

Field termination requires careful attention to detail to avoid performance issues, and the quality of the connection may be influenced by the installer's proficiency.

The choice between pre-terminated and field-terminated fiber cables depends on specific project requirements, budget considerations, and the desired balance between installation speed and customization options.

When Should I Use / When should I not use Pre-Terminated Fiber Optic Assemblies?

Determining when to use or not use pre-terminated fiber optic assemblies depends on various factors, each influencing the decision-making process for a particular project.

Pre-terminated cable assemblies are ideal for scenarios where speed and efficiency in installation are critical. These assemblies come factory-tested and ready-to-use, making them advantageous in environments where minimizing installation time is a priority.

Additionally, projects with limited access to skilled labor or those requiring a plug-and-play solution often benefit from the convenience of pre-terminated assemblies.

However, there are instances where pre-terminated assemblies may not be the most suitable choice. Projects with unique specifications or non-standard configurations that demand on-site customization might find field-terminated solutions more appropriate.

Additionally, when dealing with large-scale installations that involve varying cable lengths, field-terminated options allow for more precise adjustments to meet specific requirements.

Budget considerations may also play a role, as pre-terminated assemblies may have a higher upfront cost compared to field-terminated options, especially if customization is a significant factor in the project.

In essence, the decision to use pre-terminated fiber optic assemblies should be based on a careful evaluation of project requirements, installation constraints, and cost considerations.

Superior Customer Service // Free Technical Support // Fast Lead Times

888-568-1230

888-568-1230