Our pre-terminated Fiber Optic Cables offer a plug and play custom fiber solution for seamless installation in electrical conduits or within walls for both residential and commercial settings. They ensure the efficient delivery of audio, video, data, fiber internet, smart controls, and support HDMI in 4k and 8k. Additionally, hybrid combo options with bundled electric wires are also available.

All our Pre Terminated Fiber Optic Assemblies are custom made in the USA at the time of your order, are made to your exact specifications, and come with test results.

These Pre-terminated assemblies can be ordered in either indoor (plenum), indoor/outdoor, tactical, outdoor variations in non-armored or armored.

Strand counts from 2, 4, 6, 12 , 24 and all the way up to 288 strand fiber counts in the fiber core of Multimode OM1, OM2, OM3 OM4, OM5 or Singlemode!

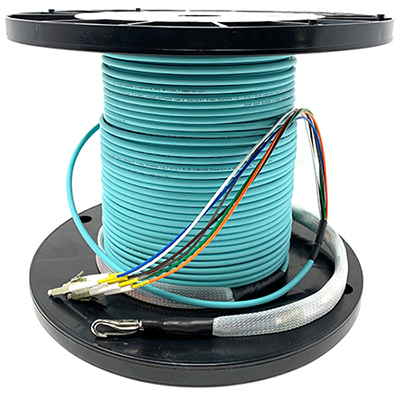

A pulling eye is recommended and can be factory installed. The pulling eye (and associated cable netting) will protect the preterminated ends during the pull.

This product is a great time and money saver for those who need to install fiber optic cabling.

What is a Pre Terminated Fiber Optic Cable Assembly?

A Pre-Terminated Fiber Optic Cable Assembly refers to a specialized and ready-made fiber optic cable solution that comes with connectors already installed at both ends. This premade fiber solution gives installers more of a "plug and play" option.

Unlike traditional on-site fiber optic installations, which involve field termination of connectors, pre-terminated assemblies are factory-manufactured with precision and tested for optimal performance. These assemblies typically include fiber optic cables, connectors, and sometimes additional components like splitters or adapters, all integrated and tested before being shipped to the installation site.

The pre-termination process is performed in a controlled environment, ensuring higher quality and reliability compared to field terminations. LANshack makes sure that test results are provided with every pre-terminated assembly we sell.

This results in quicker and more efficient installations, reducing downtime and potential errors associated with on-site terminations. Additionally, pre-terminated assemblies are custom-made to meet specific length requirements, minimizing excess cable and reducing the need for additional splicing or connectors on-site.

Pre-terminated assemblies let you extend your network to any distant location. Check out this video to see more.

These assemblies are widely used in various applications, including data centers, telecommunications networks, and enterprise environments where high-speed and reliable data transmission are crucial.

The use of pre-terminated fiber optic cable assemblies has become increasingly popular as organizations seek cost-effective, scalable, and high-performance solutions for their network infrastructure needs.

Advantages of Pre-Terminated Assemblies for Installers

Pre-terminated fiber optic assemblies offer a myriad of advantages for installers in various settings. Firstly, these assemblies streamline the installation process, significantly reducing the time and effort required for setup. With connectors already attached and tested, installers can avoid the intricacies of field termination, ensuring a quicker and more efficient deployment. This time-saving aspect not only accelerates project completion but also minimizes the potential for errors during field terminations, enhancing overall reliability.

In addition to time efficiency, pre-terminated fiber optic assemblies contribute to enhanced performance and reliability. The factory-controlled termination process ensures precision and consistency in connector termination, resulting in optimal signal integrity. This precision is particularly crucial in high-speed data transmission applications, such as 4k and 8k video, where signal quality is paramount. By relying on pre-terminated assemblies, installers can be confident in the reliability of their installations, knowing that each connection meets stringent industry standards.

Furthermore, pre-terminated fiber optic assemblies offer flexibility in deployment scenarios. Their compatibility with various environments, including residential and commercial spaces, allows for versatile applications. Whether it's pulling through electrical conduits or routing within walls, these assemblies adapt seamlessly to diverse installation requirements. The availability of hybrid options, incorporating bundled electric wires, further enhances versatility, addressing the evolving needs of modern installations that may involve a combination of audio, video, data, and power requirements.

Fiber Types and Which You May Need

When it comes to selecting your fiber type, the biggest reason you may need something different for your installation is speed.

The Multimode core sizes come in different classifications: OM1, OM2, OM3, OM4, and OM5 while singlemode only has one.

Multimode fiber solutions, featuring larger cores for transmitting multiple modes, can handle more data than single-mode options.

However, they operate at slower speeds and carry a higher risk of attenuation, making them suitable for short-range networks. These cables come with either step or graded index cladding, each affecting mode refraction differently.

OM1

OM1 or 62.5/125 Fiber is the largest fiber core, therefore the light has more time to bounce around or reflect, and it takes longer for it to reach the end point.

OM1 Fiber supports 1 Gigabit Ethernet to 275 meters and can support 10 Gigabit Ethernet up to 33 meters.

OM1 fiber is not the best choice for a 10 Gig network as it has the lowest data carrying capacity and shortest distance limitations.

OM2

OM2 Fiber is in the 50/125 classification but is more in line with OM1 fiber in terms of speed and distance.

OM2 fiber can support 1 Gigabit ethernet up to 550 meters but can only support 10 Gigabit Ethernet up to 82 meters.

With the advance of OM3 fiber, OM2 has become essentially phased out in the industry.

OM3

OM3 is usually just referred to as 10 Gig since it's generally the best choice for 10 Gigabyte networks. Multimode fiber was designed specifically for that purpose.

OM3 fiber can support 1 Gigabit ethernet up to 550 meters and can support 10 Gigabit Ethernet up to 300 meters. In addition, it can also support 40 Gig up to 100 meters, and 100 Gig up to 70 meters.

OM4

OM4 fiber is backwards compatible with OM3 fiber and was developed for VCSEL laser transmission.

OM4 fiber can support 10 Gigabit ethernet up to 550 meters and it can also support 40 and 100 Gig up to 150 meters.

OM5

OM5 fiber also known as SWDM or Shortwave Wavelength-division multiplexing fiber is downwards compatible with OM4 fiber and has the ability to use four wavelengths across the 850 to 950 nm range.

But for comparative purposes as a single signal, OM5 fiber can support 10 Gigabit ethernet up to 550 meters and it can also support 40 and 100 Gig up to 150 meters.

Singlemode

Singlemode fiber has the smallest fiber core, and therefore there is less room for the light to reflect and has less attenuation.

Single-mode cables, with their thin glass fiber cores transmitting single rays of light, are optimal for long-distance connections due to their resistance to attenuation. However, their intricate production processes make them pricier than their multimode counterparts.

Singlemode fiber can transmit light at much longer distances, but OM3/OM4/ and OM5 multimode fiber supports a higher data rates.

Singlemode fiber can support 1 Gigabit ethernet up to 5 kilometers and it can also support 10 Gigabit ethernet up to 10 kilometers.

What Pre Terminated Fiber Jacket Types Should I Use?

Selecting the appropriate pre-terminated fiber jacket types is a critical decision in ensuring the success of any fiber optic installation. The choice of jacket type depends on the specific environmental conditions and the intended application. For indoor installations, a plenum-rated jacket may be suitable, as it complies with fire safety codes and is designed for use in air handling spaces. Outdoor installations, on the other hand, often require rugged and weather-resistant jackets to withstand exposure to elements. Armored jackets provide additional protection against physical damage in more demanding environments. In high-density data centers, low-smoke, zero-halogen (LSZH) jackets are preferred to minimize the emission of toxic fumes in the event of a fire. Carefully considering the environmental factors and application requirements will guide the selection of pre-terminated fiber jacket types, ensuring durability, safety, and optimal performance in any given scenario.

For an easy to understand guide, check out this video.

Indoor (Plenum):

This is a plenum rated distribution type fiber with a durable jacket which provides added protection during installation. It is suitable for all indoor applications where fiber optic cabling is needed. It utilizes 900µm Tight Buffers, Aramid yarn strength members, and exclusive use of Corning® optical fibers. This cable is rated for all indoor installations, including plenum rated spaces. A cable rated for plenum installation will have low-smoke characteristics as defined by the NFPA (National Fire Protection Agency).

Indoor/Outdoor:

Indoor/Outdoor cables are approved for use in underground conduits, even if the possibility of water infiltration exists due to its water blocking aramid strength members. Fiber construction is with 900µm Tight Buffers, and exclusive use of Corning® optical fibers. It can also be used for standard Outdoor applications since it is UV resistant, but it is not rated for direct burial (see Outdoor Fiber). The advantage of using Indoor/Outdoor over standard Outdoor cable is that it does not have the 50 foot restriction for indoor installation that standard outdoor cable has. It has a durable jacket that adds extra protection during installation and in rugged applications.

Tactical:

Our rugged tactical assemblies provide high impact and crush resistant - they can withstand a heavy vehicle and high foot traffic. A Tactical Epoxy Breakout Kit included in every assembly, as well as one metal pull hook for fast deployment in the field. A protective mesh basket is included on both ends, and the connectors are commercial grade and water resistant. This fiber has superior performance in wide temperature ranges, and the assemblies are tested to meet MIL-PRF-85045. Exclusive use of Corning® optical fibers. This fiber is suitable for indoor or outdoor applications, and for temporary or permanent installations. This tactical fiber is commonly used for deployment situations where the fiber needs to be deployed fast and reeled back up when done, therefore it is offered with Schill Tactical Deployment reels as an additional option.

Indoor plenum rated interlocking armor custom pre-terminated fiber optic cable assemblies

Our QuickTreX indoor plenum rated interlocking armor custom pre-terminated fiber optic cable assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, and multi-floor deployment where select fibers are used at each floor. Interlocking armored fiber optic cable eliminates the need for an indoor innerduct or conduit. This cable consists of an aluminum interlocking armor jacket encapsulated with plenum-rated PVC overall jacket, with a PVC inner jacket with tight buffered fibers surrounded by yarn acting as a strength member, and exclusive use of Corning® optical fibers. This cable still remains flexible for easy installation while also being crush and rodent resistant. Although this cable contains metal, it is still lightweight and flexible with about an 8-inch bend radius. This cable is rated for all indoor installations, including plenum-rated spaces. These indoor plenum, single-mode and multi-mode assemblies are made in the USA with Corning glass by skilled technicians under controlled conditions and come to you fully tested and ready for immediate installation. Our OM1 indoor plenum rated interlocking armor assemblies are available in 1 through 24 strands with the following connector options: LC, SC, ST, and FC. We can custom make these fiber optic assemblies in lengths from 10 to 5000 feet and install pulling eyes in one or both ends. Pre-terminated, armored fiber optic assemblies offer a true plug-and-play solution for your fiber optic network. Our indoor interlocking armored pre-terminated fiber optic assemblies include the following armored fiber optic cable types: multimode OM1 62.5/125 pre-terminated fiber optic assemblies, indoor plenum-rated multimode OM3 50/125 pre-terminated fiber optic assemblies, indoor plenum-rated multimode OM4 50/125 pre-terminated fiber optic assemblies, and indoor plenum-rated single-mode OS2 9/125 pre-terminated fiber optic assemblies.

Ultra Thin Indoor Armored Pre-Terminated Fiber Optic Assemblies

Our ultra-thin armored pre-terminated fiber optic assemblies utilize Micro Armor Fiber™, a revolutionary designed fiber optic cable that provides a perfect solution for your fiber optic installs and usage. Instead of a traditional interlocking armor, it utilizes stainless steel coil technology. This allows for the cable to remain extremely flexible while also being crush and rodent resistant. Micro Armor Fiber™ features the smallest outer diameter compared to conventional armored fiber optic cable in size and flexibility. Its lightweight and great flexibility make pulling and installation faster and easier. These assemblies are typically up to 65 percent smaller in diameter and 75 percent lighter than the traditional aluminum interlocking armor cable. These assemblies provide a perfect combination of strong armor and maximum bend radius. Choosing an armored jacket helps save time and money in indoor applications where innerduct or conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor distribution cable, it outweighs its overall price when compared to the cost of purchasing innerduct/conduit, indoor fiber, and installation for both.

Our pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, multi-floor deployment where select fibers are used at each floor, or intra-building backbones. Our indoor plenum-rated jacket assemblies are rated for all indoor installations, including plenum-rated spaces. A cable rated for plenum installation will have low-smoke characteristics as defined by the NFPA (National Fire Protection Agency).

Indoor/Outdoor Plenum Rated Interlocking Armor Pre-Terminated Fiber Optic Cable Assemblies

Our indoor/outdoor plenum-rated interlocking armored custom pre-terminated fiber optic cable assemblies help save time and money in indoor and outdoor applications where innerduct or conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor distribution cable, it outweighs its overall price when compared to the cost of purchasing innerduct/conduit, indoor fiber, and installation for both. This fiber is suitable for indoor and outdoor use, so there is no 50-foot fire code requirement traditionally found with outdoor (OSP) cable. Note: If part of your run requires conduit usage, you must have at least a 3" conduit in place with sweeping bends.

Interlocking armored cables are standard distribution cables inside a spirally wrapped aluminum interlocking armor with a heavy-duty outer jacket. This combination provides superior crush resistance. This type of cable is also useful for warehouses or attic areas where the presence of rodent chew hazards may exist. This indoor/outdoor interlocking armored cable has a water-blocking aramid yarn strength member surrounding the fiber optic strands and a UV-resistant outer jacket, making it a very versatile and perfect choice for a large variety of installations.

Our pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, multi-floor deployment where select fibers are used at each floor, or intra-building backbones. Our indoor/outdoor plenum-rated jacket assemblies are rated for all indoor installations, including plenum-rated spaces. A cable rated for plenum installation will have low-smoke characteristics as defined by the NFPA (National Fire Protection Agency).

Ultra Thin Indoor/Outdoor Armored Pre-Terminated Fiber Optic Assemblies

Our indoor/outdoor ultra-thin armored pre-terminated fiber optic assemblies utilize Micro Armor Fiber™, a revolutionary designed fiber optic cable that provides a perfect solution for your fiber optic installs and usage. Instead of a traditional interlocking armor, it utilizes stainless steel coil technology. This allows for the cable to remain extremely flexible while also being crush and rodent resistant. Micro Armor Fiber™ features the smallest outer diameter compared to conventional armored fiber optic cable in size and flexibility. Its lightweight and great flexibility make pulling and installation faster and easier. These assemblies are typically up to 65 percent smaller in diameter and 75 percent lighter than the traditional aluminum interlocking armor cable. These assemblies provide a perfect combination of strong armor and maximum bend radius. Choosing an armored jacket helps save time and money in indoor and outdoor applications where conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor distribution cable, it outweighs its overall price when compared to the cost of purchasing innerduct/conduit, indoor fiber, and installation for both. This fiber is suitable for indoor and outdoor use, so there is no 50-foot fire code requirement traditionally found with outdoor (OSP) cable. This indoor/outdoor armored cable has a water-blocking aramid yarn strength member surrounding the fiber optic strands and a UV-resistant outer jacket, making it a very versatile and perfect choice for a large variety of installations.

Our pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, multi-floor deployment where select fibers are used at each floor, or intra-building backbones. Our indoor/outdoor plenum-rated jacket assemblies are rated for all indoor installations, including plenum-rated spaces. A cable rated for plenum installation will have low-smoke characteristics as defined by the NFPA (National Fire Protection Agency).

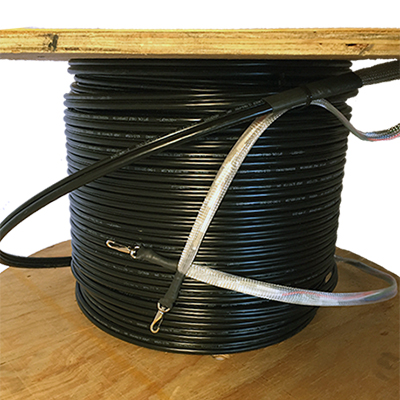

Outdoor (OSP) Gel-Filled Pre-Terminated Assembly

Our outdoor (OSP) gel-filled pre-terminated fiber optic cable assemblies are rated for almost all outdoor applications. This cable is suitable for underground installation inside conduit and pathways that are subjected to wide temperature variations or water infiltration, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. This cable is UV and crush-resistant and includes water-blocking gel. Our outdoor (OSP) pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. If installing in conduit, we recommend using at least a 2" diameter conduit to accommodate for the assembly breakout.

Note: Polyethylene (PE) OSP cable is restricted to a 50 feet run indoors due to fire-code restrictions.

Outdoor Armored Direct Burial (OSP-DB) Pre-Terminated Assembly

Our Corning Altos® outdoor armored direct burial (OSPDB) pre-terminated fiber optic cable assemblies are rated for almost all outdoor applications. These assemblies are the most durable and rugged assemblies we offer for permanent installation. They are designed for installation directly buried in trenches and underground installation where rodent chew damage is a concern, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. This jacket design also offers superior crush resistance. Our outdoor armored pre-terminated fiber optic assemblies are perfect for campus backbones, headend termination to a fiber backbone, and intra-building backbones. They are also designed for a variety of voice, data, video, and image applications. If installing in conduit, we recommend using at least a 3" diameter conduit to accommodate for the assembly breakout.

Choosing a direct burial rated jacket helps save time and money in outdoor applications where conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor/outdoor distribution cable that needs to be ran inside conduit, it outweighs its overall price when compared to the cost of purchasing conduit and then the labor involved having to pull the cable through it. This outdoor (OSPDB) armored cable has a heavy-duty polyethylene (PE) UV and waterproof jacket, corrugated steel tubing, and water-blocking swellable tape surrounding the fiber optic strands.

Note: Polyethylene (PE) OSP cable is restricted to a 50 feet run indoors due to fire-code restrictions.

Ultra Thin Outdoor Direct Bury Armored Pre-Terminated Fiber Optic Assemblies

Our outdoor (OSP) direct burial ultra-thin armored pre-terminated fiber optic assemblies utilize Micro Armor Fiber™, a revolutionary designed fiber optic cable that provides a perfect solution for your fiber optic installs and usage. Instead of a traditional interlocking armor, it utilizes stainless steel coil technology. This allows for the cable to remain extremely flexible while also being crush and rodent resistant. Micro Armor Fiber™ features the smallest outer diameter compared to conventional armored fiber optic cable in size and flexibility. Its lightweight and great flexibility make pulling and installation faster and easier. These assemblies are typically up to 65 percent smaller in diameter and 75 percent lighter than the traditional aluminum interlocking armor cable. These assemblies provide a perfect combination of strong armor and maximum bend radius.

Choosing a direct burial rated jacket helps save time and money in outdoor applications where conduit is necessary, or in industrial environments which require extra protection. Although this option is priced higher than standard indoor/outdoor distribution cable that needs to be ran inside conduit, it outweighs its overall price when compared to the cost of purchasing conduit and then having to pull the cable through it. This outdoor (OSP) armored cable has a heavy-duty polyethylene (PE) UV and waterproof jacket and water-blocking aramid yarn strength members surrounding the fiber optic strands.

Our pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. It's perfect for trenches or underground installation where rodent chew damage is a concern, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. The drawback of outdoor (OSP) cable is that it is mandated at a maximum of 50 feet run indoors due to fire-code regulations.

Outdoor (OSP) Flat Drop Pre-Terminated Assembly

Our Corning® SST-DROP™ flat outdoor (OSP) gel-filled pre-terminated fiber optic cable assemblies are rated for almost all outdoor applications. This cable is unique since it's self-supporting, meaning it can be installed aerially without a messenger, while also being durable enough for direct burial installations. If directly burying and rodents are a concern, we do recommend using our armored outdoor direct burial cable or using a conduit for extra protection. This cable is also perfect for installations inside conduit and pathways that are subjected to wide temperature variations or secured to a building or other permanent outdoor structure. Its rugged all-dielectric design makes it a popular choice for a variety of outdoor installations. Our outdoor (OSP) pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. If installing in conduit, we recommend using at least a 2 1/2" diameter conduit to accommodate for the assembly breakout.

Note: Polyethylene (PE) OSP cable is restricted to a 50 feet run indoors due to fire-code restrictions.

Outdoor (OSP) Loose Tube Pre-Terminated Assembly

Our Corning Altos® outdoor (OSP) loose tube pre-terminated fiber optic cable assemblies are rated for almost all outdoor applications. This cable is suitable for underground installation inside conduit and pathways that are subjected to wide temperature variations, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. It's a top choice for "Fiber to the Antenna" installations due to its rugged all-dielectric design. Our outdoor (OSP) pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones. If installing in conduit, we recommend using at least a 2" diameter conduit to accommodate for the assembly breakout.

Note: Polyethylene (PE) OSP cable is restricted to a 50 feet run indoors due to fire-code restrictions.

Outdoor Aerial Pre-Terminated Assembly

Our outdoor (OSP) aerial with messenger pre-terminated fiber optic cable assemblies are rated for almost all outdoor applications. These assemblies are perfect for outdoor aerial installations along utility poles without the need for cable lashing. It comes in a Figure 8 configuration, consisting of the messenger, the webbing, and the fiber optic cable. There are several advantages to the Figure 8 messenger configuration, mainly that it reduces cost by eliminating the need to purchase a separate messenger wire and lashing wire and then having to attach the assembly to the messenger wire. With our aerial with messenger assemblies, there is only one installation job, which also reduces labor costs.

This cable includes a very heavy-duty polyethylene jacket and can withstand the harshest outdoor elements. Our outdoor (OSP) pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone and intra-building backbones.

Note: Polyethylene (PE) OSP cable is restricted to a 50 feet run indoors due to fire-code restrictions.

Tactical Fiber Optic Assemblies

Our tactical fiber optic assemblies include super-strong protective sleeves on both ends. These sleeves are made of abrasion and UV-resistant Tech Flex and easily fold back on itself exposing the connectors for use. The protective sleeves are secured to the cable jacket using heat shrink tubing glue set and high-quality adhesive. These assemblies include 3-millimeter polyurethane with Kevlar sequentially labeled furcation tubing. The buffer tubes are fastened to the outer jacket using epoxy-filled breakouts. These transitions are constructed from a high-temp skeletal frame and MIL-SPEC covering with an assembled durometer hardness of D90. The connectors are premium commercial grade, water-resistant, and include superior strain relief. Protective caps are placed on all connectors to prevent contamination while not in use. A super-ruggedized galvanized steel Hubble cable bale is placed on the front end of your assembly for a secure grip and smooth deployment of your assembly.

These assemblies are fully tested using premium test equipment so you can be assured not only is your assembly built to last but it's also built to perform to the highest standards. The test results are placed on the inside of the door or printed if no reel, or a reel with no door is chosen. Also included with the test results is the SKU number and an individualized serial number. Both ends of your assembly will include a waterproof label with the part number and serial number for easy identification and traceability.

MIL-TAC Tactical Fiber Optic Assemblies

Our tactical fiber optic assemblies include super-strong protective sleeves on both ends. These sleeves are made of abrasion and UV-resistant Tech Flex and easily fold back on itself exposing the connectors for use. The protective sleeves are secured to the cable jacket using heat shrink tubing glue set, and high-quality adhesive. These assemblies include 3-millimeter polyurethane with Kevlar sequentially labeled furcation tubing. The buffer tubes are fastened to the outer jacket using epoxy-filled breakouts. These transitions are constructed from high-temp skeletal frame and MIL-SPEC covering with an assembled durometer hardness of D of D90. The connectors are premium commercial grade, water-resistant, and include superior strain relief. Protective caps are placed on all connectors to prevent contamination while not in use. A super-ruggedized galvanized steel Hubble cable bale is placed on the front end of your assembly for a secure grip and smooth deployment of your assembly.

These assemblies are fully tested using premium test equipment so you can be assured not only is your assembly built to last but it's also built to perform to the highest standards. The test results are placed on the inside of the door or printed if no reel, or a reel with no door is chosen. Also included with the test results is the SKU number and an individualized serial number. Both ends of your assembly will include a waterproof label with the part number and serial number for easy identification and traceability.

Custom QuickTreX Pre-Terminated Assemblies with Neutrik® OpticalCon®

Our QuickTreX OpticalCon Duo® fiber optic assemblies harness the power of the Neutrik® brand tactical connector, with tactical-grade fiber to provide a superior rugged product. QuickTreX® tactical and rugged pre-terminated fiber optic assemblies are designed to withstand the harshest of environments. This assembly is military-approved and is ideal for audio and broadcast networks.

The OpticalCon Duo cable connector houses a standard optical LC-Duplex connector in a ruggedized and durable all-metal housing. A spring-loaded push-pull locking mechanism provides superior protection for the connectors, and the fiber provides excellent cable retention utilizing aramid yarn. An automatically operated sealing cover protects the connectors from all contaminants like dirt and dust.

Our tactical and rugged assemblies can optionally be installed on a heavy-duty Schill deployment reel, designed for quick deployment and retrieval. These Schill reels include a door which houses the connectors for safe and secure storage while not in use. This assembly is made in the USA by skilled technicians under controlled conditions and comes to you fully tested and ready for immediate use. The test results are placed on the inside of the door.

Hybrid Pre-Terminated Fiber Optic Assembly with Power

Our hybrid indoor/outdoor ultra-thin armored pre-terminated fiber optic assemblies utilize Micro Armor Fiber™, a revolutionary designed fiber optic cable that provides a perfect solution for your fiber optic installs and usage. Instead of a traditional interlocking armor, it utilizes a stainless steel coil technology. This allows for the cable to remain extremely flexible while also being crush and rodent resistant. Micro Armor Fiber™ features the smallest outer diameter compared to conventional armored fiber optic cable in size and flexibility. Its lightweight and great flexibility make pulling and installation faster and easier. These assemblies are typically up to 65 percent smaller in diameter and 75 percent lighter than the traditional aluminum interlocking armor cable. They provide a perfect combination of strong armor and maximum bend radius.

Choosing an armored jacket helps save time and money in indoor and outdoor applications where conduit is necessary, or in industrial environments that require extra protection. Although this option is priced higher than standard indoor distribution cable, it outweighs its overall price when compared to the cost of purchasing innerduct/conduit, indoor fiber, and installation for both. This fiber is suitable for indoor and outdoor use, so there is no 50-foot fire code requirement traditionally found with outdoor (OSP) cable. This indoor/outdoor armored cable has a water-blocking aramid yarn strength member surrounding the fiber optic strands and a UV-resistant outer jacket, making it a very versatile and perfect choice for a large variety of installations.

Our pre-terminated fiber optic assemblies are perfect for headend termination to a fiber backbone, termination of fiber rack systems, multi-floor deployment where select fibers are used at each floor, or intra-building backbones. Our indoor/outdoor-rated jacket assemblies are rated for all indoor installations.

What Fiber Stand Counts Do We Offer?

When working with fiber, an important thing to keep in mind is that with standard equipment, you will need two fiber strands to make a connection: one transmit signal (Tx), and one receive signal (Rx).

So, when you purchase a 2 Strand Assembly, you will have one fiber pair, and will be able to complete one connection.

When you purchase a 4 Strand Assembly, you will have two fiber pairs, and two connections, and with a 6 strand assembly, three fiber pairs, and three connections, and so on.

We offer some assemblies in strand counts up to 144, which would provide 72 fiber connections. For higher strand counts we also offer:

Fiber Connector Types We Offer

LC

The LC fiber optic connector is a small form factor connector that snaps in. It includes a 1.25 mm ceramic ferrule. The LC connector is very popular and offers great performance for high density or compact areas. Most SFP modules accept LC connectors.

SC

The SC fiber optic connector is a snap-in connector that latches with a push-pull motion. It includes a 2.5 mm ceramic ferrule. This connector and is commonly used because it provides excellent performance. Many media converters accept SC connectors.

ST

The ST fiber optic connector is typically metallic and utilizes a spring-loaded twist and lock style connection with a bayonet mount. It includes a 2.5 mm ferrule that is usually ceramic but can also be polymer. Many media converters accept ST connectors.

FC

The FC fiber optic connector is a metallic connector that is threaded and screws on. It includes a 2.5 mm ceramic ferrule. It’s been mostly phased out but is still sometimes used is applications where vibration and movement can become an issue.

Connector Polish Options

In Singlemode fiber, our ST and MTRJ connectors are available in an upgraded UPC polish option, and our LC, SC, and FC are available in both UPC and APC polish. APC connectors feature a fiber end face that is polished at an 8-degree angle, while UPC connectors have a slight curvature for better core alignment. The different polish options help with improving return loss, which is a measurement of reflected light.

Pulling Eyes

A pulling eye is designed to be attached to a pull string that runs the full length of your conduit. Your assembly is then pulled through the conduit via the pull string. It can also be used to pull your assembly through duct work, in wall cavities, or other areas where routing needs to take place. Our pulling eyes include a heavy-duty swivel hook to prevent the cable from twisting during the pull. The metal pull hook is attached to a designated pull string inside of your assembly usually consisting of Kevlar so that you are not pulling on the fiber strands themselves. The pulling eye includes heat shrink tubing that covers the back side of the pull hook, and the pull basket that contains your fiber optic connectors.

The pull basket is constructed with super strong polyethylene mesh that tightens itself around the strands and connectors keeping them securely in place during install. The connectors are also staggered inside of the pull basket for less bulk, and each connector is individually plastic wrapped to prevent contamination by pulling lubricants and other debris. Our pulling eyes are always recommended as they make your pull much easier while providing further protection of your connectors.

We always recommend pulling eyes on both ends, even if you’re only pulling one end of the assembly. This helps protect the back side of your assembly’s connectors and prevent damage. The pull hook can be secured on the back end to prevent twisting and flapping of your connectors during install.

Running Through Different Environments

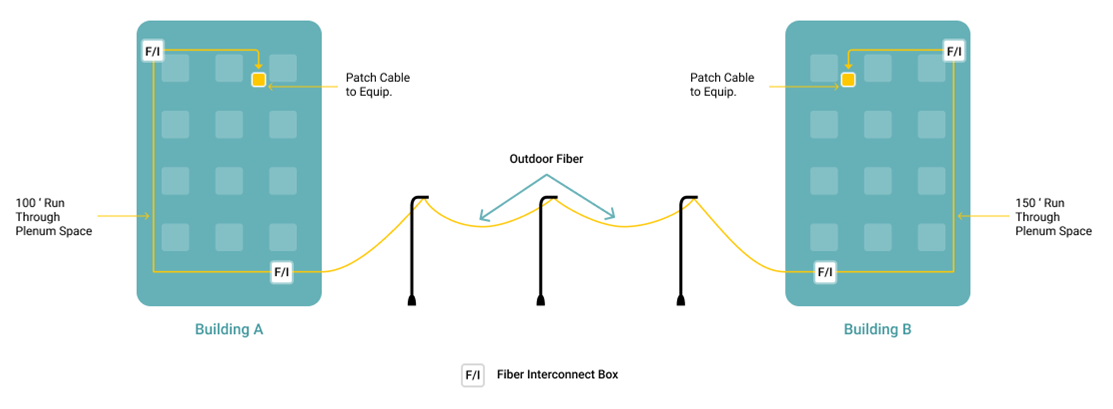

Say for example that you have a cable run that will go from building A to building B. In building A, there is a 100 foot run through a plenum space. Then the cable must run overhead from pole to pole for a distance of 550 feet to building B. In building B, the cable must be run for a distance of 150 feet through a plenum space. Obviously, this cannot be done with a single cable. The way to do this is with three separate cables. The pre terminated fiber optic cables can be joined together in buildings A & B by the use of Fiber Optic Distribution boxes. See diagram below:

Here's a video that explains how to install a pre-terminated fiber optic assembly with an easy to follow guide.

3) How To Take An Accurate Measurement

It is extremely important to take an accurate measurement when planning an order for a custom preterminated fiber optic cable assembly. These custom assemblies cannot be returned unless out of box defective.

We recommend that you fish through a small (200 lb. rated) polypropylene pull string from end to end (termination point to termination point). The string should follow the exact path and be shaped to the run in the exact way that the final cable will be installed, from end to end. At each termination end, shape the string over to the termination point and add at least 15 feet and cut the string. Once this has been done on both ends the string should be removed. You may want to replace the string with a heavier rope for later pulling of the cable (see installation recommendations item #2 below). Once the string is removed, take an accurate measurement and record it. It is always better to have a cable that is longer than shorter for obvious reasons. Slack coils of the cable may be put by each termination point.

4) Pulling Eye Recommendations for Pre-Terminated Assemblies

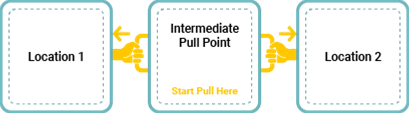

Optional pulling eyes are highly recommended. The pulling eye pulling eye (and associated cable netting) will protect the pre terminated ends during the pull. In many cases, pulling is not done from point to point, but rather from an intermediate point pulling back in each direction to each termination location. In that scenario, you will need to order the cable with two pulling eyes. In many cases, a cable run is planned to pull direct from point to point. When the installation begins, occasionally, the decision is made to pull from an intermediate point rather than from point to point (in which case you'll be glad that you ordered the extra pulling eye).

Pre Terminated Fiber Installation Recommendations

1) Planning the Run

1a) Underground Conduits: We recommend that underground conduits, if newly installed, should be a minimum size of between 1½" to 2". If the run is long, or if you anticipate the possibility of additional future pulls; Then you may want to install a conduit of up to 4" (or greater). Once the trench is dug, the installation of the conduit is comparably easy and inexpensive. You may also want to consider installing additional conduits for future use.

1b) Conduit Installations General Information:

-

Try to design the conduit run with a few bends as possible. If there are too many bends in the run then you may consider installing junction boxes in lieu of bends. Note: There is some controversy on installing junction boxes in lieu of bends. Read more Information.

-

Use plastic bushings on conduit ends to avoid damage to the cable during the pull.

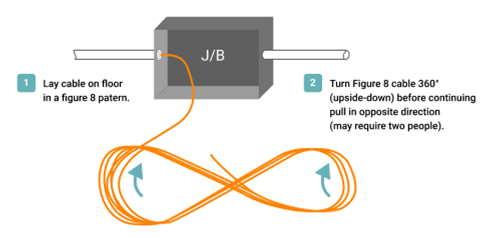

1c) In Buildings: It is not necessary to pull fiber optic cable in innerduct. Innerduct is strictly a personal preference. The following instruction takes into consideration that you will pull the fiber optic cable directly into the ceiling or other space. Plan for straight pulls only (point A to point B). Diagonal pulling across an area will be OK but it would make for a neater and more professional installation to install the cable at an angle that is parallel to a wall. Do not attempt to pull the cable around a corner, even if you plan on having a person feeding it from hand to hand around the corner. Instead, pull all of the cable out (at the turn) and lay it on the floor in a figure 8 pattern (See Installing - item #2e below).

2) Installing the pre-term fiber cable

2a) Rope Size: It is important to use a rope size that give minimal stretching during the pull. Stretching of the rope is undesirable for several reasons including that it makes for a very unstable pull, and takes away control from those doing the pulling. This is why we do not recommend using 200 lb. pull string (aka: jetline) to pull the cable. We recommend a heavier rope that is anywhere from a 1/4" to 1/2" in thickness. The thickness of the rope should increase with greater pull lengths. Have the pull rope installed before the cable pulling crew arrives for maximum efficiency.

2b) Communication between the person feeding and the person pulling the cable is absolutely essential. If the person feeding runs into a snag then the puller must stop immediately to avoid damage to the cable. Walkie-talkies would come in handy for this purpose. Use of great pulling force is not recommended and will likely damage the terminations and/or the cable.

2c) Use a generous amount of cable pulling lubricant on the entire run, especially on the leader (pulling eye & mesh). The person may stop the cable pull from time to time to prepare and apply more lubricant. Use only lubricant that is expressly designed for cable pulling. When working in freezing temperatures, use a lubricant that is designed not to freeze.

2d) Do make every effort to pull cables from a conduit in as straight an angle as possible. Pulling on an angle can cause damage to the cable.

2e) How to Handle Slack: When pulling cable out from a conduit or ceiling, it will become necessary to coil up the cable in preparation to pull it in another direction. Fiber Optic cable has a "memory". That is to say that it holds it's contour that it formed while being on a reel. Do not try to re-coil the cable in a circular pattern; Instead use a figure - 8 pattern as shown in the illustration. When you are finished pulling out all of the slack, turn the figure - 8 cable 360° (upside down) and proceed to setup to pull it in the other direction.

Removing the Pull Eye:

Follow Building Codes: Always obey all local, and national, fire and building codes. Be sure to "firestop" all cables that penetrate a firewall. Use plenum rated cable where it is mandated, etc.

Pre-Terminated Fiber Cable vs. Field-Terminated Fiber Cable

When comparing pre-terminated fiber optic cable to field-terminated fiber cable, it is essential to understand the advantages and considerations associated with each option. Pre-terminated fiber cable assemblies come with factory-installed connectors, making them ready for immediate deployment upon arrival. This minimizes installation time and reduces the need for specialized labor, ensuring a quicker and more straightforward installation process. The pre-terminated fiber optic assemblies are precisely manufactured and tested in controlled environments, ensuring high-quality connections and optimal performance. On the other hand, field-terminated fiber cables require connectors to be installed on-site during the installation process. While this option offers more flexibility in terms of cable length customization, it typically demands more time and skilled labor for termination. Field termination requires careful attention to detail to avoid performance issues, and the quality of the connection may be influenced by the installer's proficiency. The choice between pre-terminated and field-terminated fiber cables depends on specific project requirements, budget considerations, and the desired balance between installation speed and customization options.

When Should I Use / When should I not use Pre-Terminated Fiber Optic Assemblies?

Determining when to use or not use pre-terminated fiber optic assemblies depends on various factors, each influencing the decision-making process for a particular project.

Pre-terminated cable assemblies are ideal for scenarios where speed and efficiency in installation are critical. These assemblies come factory-tested and ready-to-use, making them advantageous in environments where minimizing installation time is a priority.

Additionally, projects with limited access to skilled labor or those requiring a plug-and-play solution often benefit from the convenience of pre-terminated assemblies.

However, there are instances where pre-terminated assemblies may not be the most suitable choice. Projects with unique specifications or non-standard configurations that demand on-site customization might find field-terminated solutions more appropriate.

Additionally, when dealing with large-scale installations that involve varying cable lengths, field-terminated options allow for more precise adjustments to meet specific requirements.

Budget considerations may also play a role, as pre-terminated assemblies may have a higher upfront cost compared to field-terminated options, especially if customization is a significant factor in the project.

In essence, the decision to use pre-terminated fiber optic assemblies should be based on a careful evaluation of project requirements, installation constraints, and cost considerations.

888-568-1230

888-568-1230