Free shipping on orders over $250 Use code SHIP4FREE

Free shipping on orders over $250 Use code SHIP4FREE

Fast Lead Times | Fast Shipping

- Pre-Terminated Fiber Optic Assemblies

- back

- In Stock Pre-Terminated

- Indoor Plenum

- Indoor / Outdoor

- Indoor Plenum Interlock Armor

- Indoor Ultra Thin Armored

- I/O Plenum Interlock Armor

- Indoor / Outdoor Ultra Thin Armored

- Outdoor SST Drop Self Supporting

- Outdoor Loose Tube (OSP)

- Outdoor Gel Filled (OSP)

- Outdoor Ultra Thin Armored (OSP)

- Outdoor Armored Direct Burial (OSP)

- Outdoor Aerial with Messenger (OSP)

- Tactical and Rugged Deployable

- back

- Multimode OM3 Tactical

- Multimode OM4 Tactical

- Singlemode Tactical

- OpticalCON Tactical

- back

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber SM - Broadcast Tactical

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber SM - Broadcast Tactical

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber SM - Broadcast Tactical

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO SM Inline Coupler

- DUO OM3 Inline Coupler

- DUO APC Inline Coupler

- OpticalCON MTP 12 Chassis Connector

- 2 Port D-Series Wall Plate

- 1 Port D-Series Wall Plate

- HMA Expanded Beam Tactical

- back

- 2 Channel/Fiber

- 4 Channel/Fiber

- Ex. Beam 2 CH/F MM OM3 Chassis Conn.

- Ex. Beam 4 CH/F MM OM3 Chassis Conn.

- 4 CH to 2 X 2 CH OM3 Ex. Beam

- 2 CH OM3 Ex. Beam to OpticalCON Duo

- 4 CH OM3 Ex. Beam to OpticalCON Quad

- 4 CH OM3 Ex. Beam to 2 x OpticalCON Duo

- Ex. Beam Color Coding Ring

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Ex. Beam 1 CH/F MM OM3 Rotary Joint

- Ex. Beam 2 CH/F MM OM3 Conn. Mod.

- Ex. Beam 4 CH/F MM OM3 Conn. Mod.

- Mil-Tac Tactical Assemblies

- Neutrik® OpticalCON®

- back

- OpticalCON DUO

- back

- 2 Fiber SM - Broadcast Tactical

- 2 Channel SM - Mil-Tac Extreme

- 2 Fiber SM Hybrid SMPTE

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber OM3 - Mil-Tac Extreme

- 2 Fiber SM - Tactical Patch Cable

- 2 Fiber OM3 - Tactical Patch Cable

- SM Duo to 2 Simplex Breakout Assembly

- OM3 Duo to 2 Simplex Breakout Assembly

- DUO Chassis Connector

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO OM3 Inline Coupler

- DUO SM Inline Coupler

- DUO APC Inline Coupler

- 1 Port D-Series Wall Plate

- OpticalCON QUAD

- back

- 4 Fiber SM - Broadcast Tactical

- 4 Fiber SM - Mil-Tac Extreme

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber OM3 - Mil-Tac Extreme

- 4 Channel SM Lite Tac Patch

- 4 Fiber OM3 - Tac Patch Cable

- SM Quad to 4 Simplex Breakout Assembly

- OM3 Quad to 4 Simplex Breakout Assembly

- QUAD Chassis Connector

- Neutrik D-Series Patch Panel

- QUAD OM3 Inline Coupler

- QUAD SM Inline Coupler

- QUAD APC Inline Coupler

- SHUTTER BUDDY

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- OpticalCON MTP

- back

- 12 Fiber SM - Broadcast Tactical

- 12 Fiber SM - Mil-Tac Extreme

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber OM3 - Mil-Tac Extreme

- 12 Channel MTP SM Lite Tac Patch

- 12 Fiber OM3 - Tac Patch Cable

- SM MTP to 12 Simplex B/O Assembly

- OM3 MTP to 12 Simplex B/O Assembly

- OpticalCON MTP 12 Chassis Connector

- Neutrik D-Series Patch Panel

- OM3 Multimode Inline Coupler

- Singlemode APC Inline Coupler

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Hybrid Fiber + Power

- MTP Trunk Cables, Fanouts, & Cassettes

- back

- Indoor MTP Trunks

- Indoor/Outdoor MTP Trunks

- Indoor Armored MTP Trunks

- In/Outdoor Armored MTP Trunks

- Outdoor Loose Tube MTP Trunks

- Outdoor Self Sup. Drop MTP Trunks

- Outdoor Micro Armored MTP Trunks

- Outdoor Armored MTP Trunks

- IP68 Weatherproof OptiTip® HMFOC

- Stock Indoor MPO Cables

- Stock In/Outdoor MTP/MPO Trunks

- Indoor MTP Fanouts

- back

- Multimode OM3 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Multimode OM4 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Singlemode 9/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- Indoor / Outdoor MTP Fanouts

- MTP OSP Loose Tube Fanout Cable

- MTP OSP Armored Fanout Cable

- Stock Indoor MPO Fanout Cables

- Cassettes and Components

- back

- OM3 Cassettes

- OM4 Cassettes

- Singlemode Cassettes

- Enclosures

- back

- Super High Density 5 panel (1U)

- Super High Density 14 panel (2U)

- Lightweight Aluminum 2 panel (1U)

- Lightweight Aluminum 3 panel (1U)

- Lightweight Aluminum 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 2 Panel (1U)

- Multilink 3 panel (1U)

- Multilink 4 panel (2U)

- Multilink 6 panel (2U)

- Multilink 12 panel (2U)

- 4 panel (1U) UHD Patch Panel

- Couplers and Adapter Panels

- MTP/MPO to LC LGX Cable Harness

- Fiber Patch Cables, Enclosures, & Couplers

- back

- Fiber Enclosures & Adapter Panels

- back

- Rack Mount Termination Boxes

- back

- Lightweight Aluminum 2 panel (1U)

- Multilink 2 Panel (1U)

- 2 panel (1U) Slide Out 16 AWG

- Lightweight Aluminum 3 panel (1U)

- 3 panel (1U) Swing Out Splice Box

- 3 panel (1U) LGX Patch Panel

- Multilink 3 panel (1U)

- 3 panel (1U) Slide Out 16 AWG

- 4 panel (1U) UHD Patch Panel

- Lightweight Aluminum 4 panel (2U)

- Multilink 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Multilink 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 12 panel (2U)

- Super High Density 5 panel (1U)

- Wall Mount Termination Boxes

- back

- QuickTreX 2 Adapter / 1-4 Fiber

- Lightweight Aluminum 1 panel

- Heavy Duty Steel 1 panel

- Multilink 1 Panel

- Multilink 1 Panel w/ Splice

- Lightweight Aluminum 2 panel

- Multilink 2 Panel

- Lightweight Aluminum 4 panel

- Multilink 4 Panel

- Multilink 4 Panel with Splice

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- Outdoor Harsh Environment

- back

- QuickTreX 1 Adapter / 1-2 Fiber

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- Multilink 2 Panel Outdoor

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- Multimode OM1 Adapter Panels

- Multimode OM2/3/4 Adapter Panels

- back

- QuickTreX 12 Fiber LC

- QuickTreX 24 Fiber LC

- Multilink 12 Fiber LC

- Multilink 24 Fiber LC

- QuickTreX 6 Fiber SC

- QuickTreX 12 Fiber SC

- Multilink 6 Fiber SC

- Multilink 12 Fiber SC

- Multilink 6 Fiber ST

- Multilink 12 Fiber ST

- QuickTreX 6 Fiber ST

- QuickTreX 12 Fiber ST

- QuickTreX 6 Fiber FC

- Corning CCH to LGX Conversion Panel

- Multimode OM5 Adapter Panels

- Singlemode Adapter Panels

- back

- QuickTreX 12 Fiber LC UPC

- QuickTreX 12 Fiber LC APC

- Multilink 12 Fiber LC UPC

- Multilink 12 Fiber LC APC

- QuickTreX 24 Fiber LC UPC

- QuickTreX 24 Fiber LC APC

- Multilink 24 Fiber LC UPC

- Multilink 24 Fiber LC APC

- QuickTreX 6 Fiber SC UPC

- QuickTreX 6 SC APC

- QuickTreX 12 Fiber SC UPC

- QuickTreX 12 Fiber SC APC

- Multilink 6 Fiber SC UPC

- Multilink 6 Fiber SC APC

- Multilink 12 SC UPC

- Multilink 12 SC APC

- MTP Adapter Panels

- Blank Adapter Panels

- Splice Trays

- Custom Fiber Optic Patch Cables

- Custom Armored Fiber Patch Cables

- Stock Tactical Fiber Patch Cables

- back

- Stock Tac SM - Duplex LC UPC - 100FT

- Stock Tac SM - Duplex LC APC - 100FT

- Stock Tac SM - Duplex SC UPC - 100FT

- Stock Tac SM - Duplex SC APC - 100FT

- Stock Tac SM - Simplex LC UPC - 100FT

- Stock Tac SM - Simplex LC APC - 100FT

- Stock Tac SM - Simplex SC UPC - 100FT

- Stock Tac SM - Simplex SC APC - 100FT

- Stock Duplex Fiber Patch Cables

- Stock Uniboot Fiber Patch Cables

- Stock Simplex Fiber Patch Cables

- Fiber Optic Couplers & Attenuators

- back

- Multimode OM1 62.5/125

- back

- LC Simplex w/ Flange

- LC Duplex w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Simplex w/ Flange and Hinged Door

- LC Quad w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM3/4 50/125

- back

- LC Duplex w/ Flange

- LC Quad w/o Flange

- LC Quad w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- MPO Coupler - MM OM3 / OM4 Aqua

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM5 50/125

- Singlemode

- back

- LC UPC Simplex w/o Flange

- LC APC Simplex w/o Flange

- LC UPC Duplex w/ Flange

- LC APC Duplex w/ Flange

- LC UPC Quad w/o Flange

- LC APC Quad w/o Flange

- SC UPC Simplex w/ Flange

- SC UPC Simplex w/o Flange

- SC UPC Simplex w/ Flange and Hinged Door

- SC APC Simplex w/ Flange

- SC APC Simplex w/o Flange

- SC APC Simplex w/ Flange and Hinged Door

- SC UPC Duplex w/ Flange

- SC APC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Simplex - Universal MM/SM w/o Flange

- Keystone Couplers & Accessories

- back

- LC Duplex MM OM1 - Ivory

- LC Duplex MM OM3 / 4 - Aqua

- LC Duplex MM OM5 - Lime Green

- LC UPC Duplex SM - Blue

- LC Duplex SM APC - Green

- SC Simplex MM OM1 - Beige

- SC Simplex MM OM3 / 4 - Aqua

- SC UPC Simplex SM - Blue

- SC APC Simplex SM - Green

- MTP Singlemode

- MTP Multimode OM3/4

- Gloss Finish Keystone Wallplates

- Easy Wallplate Bracket

- 12 Port - 1U

- 6 Port LGX Blank Keystone Adapter Panel

- MTP / MPO Couplers

- Optical Attenuators

- Fiber Optic Splitters

- Mode Conditioning Fiber Cables

- Bulk Fiber Optic Cable, Testing, & Cleaning

- back

- Unterminated Fiber Optic Cable

- Fiber Optic Pigtail Kits

- back

- OM1 62.5/125 Multimode

- OM3 50/125 Multimode

- OM4 50/125 Multimode

- OM5 50/125 Multimode

- Singlemode

- back

- 1 meter LC 6 Fiber

- 3 meter LC 6 Fiber

- 3 meter SC 6 Fiber

- 1 meter ST 6 Fiber

- 3 meter ST 6 Fiber

- 1 meter LC 12 Fiber

- 3 meter LC 12 Fiber

- 3 meter LC APC

- 3 meter LC 12 Fiber Ribbon

- 3 meter SC APC 12 Fiber

- 3 meter SC 12 Fiber

- 3 meter SC UPC 12 Fiber Ribbon

- 1 meter ST 12 Fiber

- 3 meter ST 12 Fiber

- 2 meter LC 1 Fiber

- 2 meter SC 1 Fiber

- Fiber Optic Splice Trays & Boxes

- back

- Fiber Optic Splice Enclosures

- back

- Multilink 2 Panel Outdoor

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 480 Splice Dome Enclosure

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- Multilink 1 Panel w/ Splice

- Multilink 4 Panel with Splice

- Lightweight Aluminum 1 panel

- 3 panel (1U) Swing Out Splice Box

- Fiber Optic Splice Trays

- Fiber Optic Supplies & Tools

- Fiber Optic Cleaning Products

- Fiber Optic Connectors

- Fiber Optic Test Instruments

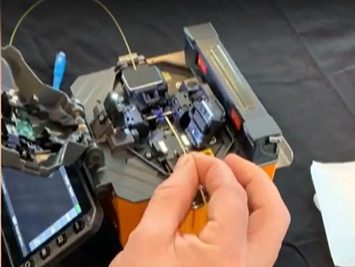

- Fusion Splicers and Accessories

- Fiber Optic Loopback Testers

- Fiber Optic Mounting Hardware

- Fiber Optic Reference Cable Kits

- Ethernet Patch Cables, Bulk Cable, & Accs.

- back

- Ethernet Patch Cables

- back

- Tactical & Rugged Deployable

- back

- Cat 5E Shielded - Custom Length

- Stock 40FT Cat 5E Shielded

- Cat 6A Shielded - Custom Length

- Stock 30FT Cat 6A Shielded

- RJ45 etherCON Coupler

- RJ45 etherCON Coupler w/ Sealing Kit

- RJ45 Cat 6A etherCON Coupler - Black

- Cat 6A etherCON Coupler - Nickel

- Neutrik D-Series Patch Panel

- Cat 6 Outdoor Inline

- Cat 6A Outdoor Panel Mount w/Cap

- Cat 6A Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- Cat 5E Custom Made in the USA

- Cat 5E Stock

- Cat 6E Custom Made in the USA

- Cat 6 Stock

- Cat 6A Custom Made in the USA

- Cat 6A Stock

- Cat 6A Stock Outdoor Armored

- Stock Cat 6A Shielded Tactical

- Outdoor Custom Made in the USA

- Cat 6 Outdoor

- Cat 8 Custom Made in the USA

- Cat 7 Stock

- Cat 8 Stock

- 110 Cat 5 Custom Patch Cables

- Custom Ethernet Cable Bundles

- Bulk Ethernet Cable

- back

- Cat 5e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, Riser (CMR), Solid, 1000 ft

- 24AWG Solid Riser , 1000 ft

- Plenum Rated Solid 1000FT USA Made

- Solid Plenum 1000FT

- 24AWG Solid Plenum, 1000 ft

- Direct Bury, CMX, Solid, 1000 ft

- 24 AWG Direct Burial Solid, 1000 ft

- 24 AWG Outdoor DB 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 5E Shielded

- Cat 6 / 6e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, 28 AWG Stranded, 1000 ft

- PVC Riser (CMR), Solid, 1000 ft

- 23AWG Solid Riser (CMR), 1000 ft

- Plenum (CMP), Solid, 1000 ft

- 23AWG Solid Plenum (CMP), 1000 ft

- Outdoor DB Solid 1000FT USA Made

- Direct Burial, CMX, Solid, 1000 ft

- Outdoor w/Messenger 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 6 / 6E Shielded Bulk Cable

- Cat 6A Unshielded

- Cat 6A Shielded

- Cat 7A Shielded

- Cat 8 Shielded

- Data & Voice Connectors

- back

- Keystone Jacks

- back

- Cat 5E - 90° Punch Down

- Cat 5E - 180°Punch Down

- Cat 6 - 90° Punch Down

- Cat 6 - 180° Punch Down

- Cat 6 Shielded 90° Punch Down

- Cat 6A - 90° Punch Down

- Cat 6A Shielded 90 Degree

- Cat 6A Shielded -180° Toolless

- Cat 8 Shielded - 90° Toolless

- Cat 8 Shielded - 90° Toolless w/Door

- RJ-11/12 Voice - 90° Punch Down

- Keystone Couplers

- Modular Plugs

- back

- Cat 5E UTP - 100 pcs USA Made

- Cat 6/6E UTP - 100 pcs USA Made

- Cat 5E/6E STP - 50 pcs USA Made

- Cat 5E/6E STP - 10 pcs USA Made

- Cat 6A STP - 50 pcs USA Made

- Cat 6A STP - 10 pcs USA Made

- Cat 8 STP - 10 pcs

- Cat 8 STP - 25 pcs

- Cat 8 STP Toolless

- Cat 6A UTP - 100 pcs

- Cat6 UTP Feed Through - 100 pcs

- Cat 6 STP Feed Through - 100 pcs

- Strain Relief Boots

- Wallplates and Surface Mount Boxes

- Splitters

- Coaxial F Connectors

- Ethernet Patch Panels

- Datacom Tools and Testers

- back

- Data & Voice Tools

- back

- PRO RJ-45 Crimper

- PRO Large OD Crimper

- Hex Crimper

- Economy RJ-45 Crimper

- PRO 110 Impact Termination Tool

- 110 Replacement Blade

- 66 Replacement Blade

- EZ RJ45 Keystone Jack Crimper

- Economy Termination Tool

- Wire and Kevlar Scissors

- Large OD Cable Stripper & Cutter

- UTP & STP Cable Stripper

- Electrical Wire Stipper

- Coaxial Cable Cutter

- Conductor Separator & Straightener

- QuickTreX Premium Adjustable Hat

- Test Equipment

- Cable Installation

- Coaxial CATV Tools

- Hand Tools

- Cable Reels

- Bulk Coaxial, Audio, and Power Cable

- back

- Co-ax RG-6 Shielded Bulk Cable

- back

- Dual Shield CCS Riser, 1000 ft WT

- Quad Shield CCS Riser, 500 ft BK

- Quad Shield CCS Riser, 1000 ft BK

- Quad Shield CCS Plenum, 1000 ft WT

- Quad Shield Solid Copper Plenum, 1000

- Dual Shield Direct Burial CCS, 1000 ft BK

- Quad Shield Direct Burial CCS, 1000 ft BK

- RG6 F Male Compression 10 Pack

- Cable Reel Deployment Caddy

- Composite Cable & Cable Bundles

- Power Cable Bulk

- Thermostat Bulk Cable

- back

- 18/2 Riser Rated, Solid Copper PVC, 500 ft

- 18/3 Riser Rated, Solid Copper PVC, 500 ft

- 18/4 Riser Rated, Solid Copper PVC, 500 ft

- 18/5 Riser Rated, Solid Copper PVC, 500 ft

- 18/6 Riser Rated, Solid Copper PVC, 500 ft

- 18/8 Riser Rated, Solid Copper PVC, 500 ft

- 20/2 Riser Rated, Solid Copper PVC, 500 ft

- 20/5 Riser Rated, Solid Copper PVC, 500 ft

- 20/8 Riser Rated, Solid Copper PVC, 500 ft

- Cable Reel Deployment Caddy

- Audio Cable Bulk

- IT Technician Tool Kits and Cases

- RJ45 Dust Plugs, Caps, and Locks

- Cable Mounting Hardware

- HDMI Cables

- Power Cords and Supplies

- Audio Video Cables

- back

- 3.5mm AUX Audio / Stereo Cables

- RCA Cables

- back

- 6 IN RCA Female to Male x 2

- 6 IN RCA Male to Female x 2

- 3 FT RCA Male to Male x 2

- 6 FT RCA Male to Male x 2

- 12 FT RCA Male to Male x 2

- 12 FT RCA Male to Male x 2

- 50 FT RCA Male to Male x 2

- 75 FT RCA Male to Male x 2

- 100 FT RCA Male to Male x 2

- 3 FT RCA Male to Male x 3

- 6 FT RCA Male to Male x 3

- 12 FT RCA Male to Male x 3

- 25 FT RCA Male to Male x 3

- 50 FT RCA Male to Male x 3

- 75 FT RCA Male to Male x 3

- Harsh Environment Cables, FTTA, RF, & IP68

- back

- OptiTip, OptiTap, HMA, & FTTA

- RF Cable Assemblies

- RF Connectors & Adapters

- back

- RF Connectors

- back

- Mini-UHF Male Crimp

- Mini-UHF Male Crimp RG-58/U

- UHF Male Solder

- UHF Male Crimp

- M Male Crimp

- N Male Crimp 50 ohm

- N Male Crimp G,G,T, 50 ohm

- N Male Crimp For Cable Group X S,G,T

- N Male Crimp RG-142/U & RG-55/U

- N Male Crimp for Cable Group B N,G,T

- SMA Male Crimp

- SMA Male Crimp RG-8/X

- SMA Male Crimp for Cable Group B N,G,T

- BNC Male Crimp RG58/U

- TNC Male Crimp RG-58/U

- TNC Male Crimp RG-8X

- RF Adapters

- Harsh Env. Fiber Optic Assemblies

- Toolkits, Cases & Enclosures

- back

- Termination Boxes

- back

- Multilink 2 Panel Outdoor

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- Network IT Toolkits

- Network IT Tool Cases

- Ethernet Patch Cables & Bulk Cable

- back

- Copper Cables and Assemblies

- Bulk Outdoor Copper Cable

- Outdoor Patch Cables

- Outdoor Accessories

- back

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Cat 6 Shielded Outdoor Panel Mount

- Cat 6 Shielded Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- 1 Gang Outdoor Wallplate

- Water-Resistant 1 Gang

- 1 Port (1 Gang) Stainless Steel Keystone Wall Plate for Mounting RJ45 Keystone Connectors and Couplers

- Network Switches, SFPs, Converters, & Racks

- back

- Network Switches

- back

- Unmanaged Gigabit

- Managed Gigabit

- Unmanaged Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 4xRJ45,1xRJ,1xSFP

- QuickTreX 12 Port GIG w/ 8xRJ45,2xRJUL,2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 2xSFP

- QuickTreX 48 Port GIG w/ 48xRJ45 & 2xSFP

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 16 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 4 Port Gigabit

- Managed Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 8xRJ45 & 2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 4xSFP/RJ45

- QuickTreX 36 Port 10G UL w/ 24xRJ45, 8xSFP, 4xSFP+

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port G w/ 4 x GIG SFP Ports + PoE Inj

- 24 Port Gigabit w/ 4 x 10Gigabit SFP Ports

- 24 Port Gigabit w/ 2 SFP Ports (Full Power)

- 24 Port Gigabit w/ 4 SFP+ Ports (Full Power)

- Unmanaged Industrial Switches

- Managed Industrial Switches

- Unmanaged Industrial PoE Switches

- back

- QuickTreX 6 Port GIG w/ 4xRJ45 & 2xSFP

- QuickTreX 10 Port GIG w/ 8xRJ45 & 2xSFP

- 4 Port Gigabit POE+ w/ 2 SFP Ports

- 4x10/100M TX PSE and 1x1000M SC MM

- 4x10/100M TX PSE + 1x10/100M

- 5 x RJ45 10/100/100BaseTX

- 5 x RJ45 1000Bast w/ 4 x Gig 30W PSE

- 8 x RJ45 10/100/1000m w/ v Boost

- 8 Port Gigabit POE+ w/ 2 SFP Ports

- 8 x Gig TX 30W PSE + 2 x 1000M TX/SFP w/ v Boost

- 8" Long Aluminum DIN Rail

- Managed Industrial PoE Switches

- Industrial Power Supplies

- SFP / QSFP Modules

- back

- Multimode SFP Modules

- Singlemode SFP Modules

- back

- 1.25 GIG - 2km at 1310nm by QuickTreX

- 10 GIG - 10km at 1310nm by QuickTreX

- 1F/BiDi Kit 1.25 GIG - 20km by QuickTreX

- 1.25 GIG - 20km at 1310nm by Unicom

- 1.25 GIG - 40km at 1310nm by Unicom

- 1.25 GIG - 80km at 1310nm by Unicom

- 1.25 GIG - 100km at 1310nm by Unicom

- 1.25 GIG - 120km at 1310nm by Unicom

- 1.25 GIG - 160km at 1310nm by Unicom

- 1.25 GIG - 180km at 1310nm by Unicom

- 10 GIG - 10km at 1310nm by Unicom

- 10 GIG - 40km at 1550nm by Unicom

- 10 GIG - 80km at 1550nm by Unicom

- 10 GIG - 100km at 1550nm by Unicom

- 10 GIG - 10km at 1310nm Cisco Compatible

- 1.25 GIG - 10km at 1310nm by Signamax

- Industrial SFP Modules

- back

- MM 1.25 GIG - 500 m / 850nm by QuickTreX

- SM 1.25 GIG - 20 km / 1310nm by QuickTreX

- MM 10 GIG - 300m / 850nm by QuickTreX

- SM 10 GIG - 10 km / 1310nm by QuickTreX

- MM GIG - 550m / 850nm by Signamax

- MM GIG - 2km / 1310nm by Signamax

- SM GIG - 10km / 1310nm by Signamax

- SM GIG - 40km / 1310nm by Signamax

- SM GIG - 40km / 1550nm by Signamax

- SM GIG - 80km / 1550nm by Signamax

- SM GIG - 110km / 1550nm by Signamax

- SM BiDI GIG - 10km 1310TX/1550RX

- SM BiDI GIG - 10km 1550TX/1310RX

- QSFP Modules

- back

- MM 40 GIG - 100m at 850nm

- SM 40 GIG - 10km at 1310nm

- SM 40 GIG - 40km at 1310nm

- MM 100 GIG - 12F MTP/MPO - 100m at 850nm

- SM 100GIG - DXLC - 2km at 1310nm

- SM 100GIG - DXLC - 40km at 1310nm

- SM 100GIG - DXLC - 80km at 1310nm

- MM 200 GIG - 12F MTP/MPO - 100m at 850nm

- MM 400 GIG - 12F MTP/MPO - 100m at 850nm

- SM 400GIG - DXLC - 2km at 1310nm

- SFP to RJ45 Modules

- Media Converters

- Network Racks and Cabinets

- back

- Free Standing Racks

- Open Frame Wall Rack

- back

- QuickTreX 16U (19"W x 18"D)

- Kendall Howard 8U (Adjustable W x 18"D)

- Kendall Howard 12U (Adjustable W x 18"D)

- Kendall Howard 12U Swing-Out

- Kendall Howard 18U Swing-Out

- Kendall Howard 12U Side Load

- Kendall Howard 12U (19"W x 12"D)

- Kendall Howard 16U (19"W x 12"D)

- Kendall Howard 12U (19"W x 18"D)

- Kendall Howard 16U (19"W x 18"D)

- Kendall Howard 2U Vertical w/ Tapped Rails

- Kendall Howard 4U Vertical w/ Tapped Rails

- Kendall Howard 2U Vertical

- Kendall Howard 4U Vertical

- Wall Mount Network Cabinets

- back

- QuickTreX 4U Swing-Out Hinged

- QuickTreX 4U Fixed

- QuickTreX 6U Swing-Out Hinged

- QuickTreX 6U Fixed

- QuickTreX 9U Swing-Out Hinged

- QuickTreX 12U Fixed

- 6U Wall Mount - Glass Door

- 6U Wall Mount - Solid Door

- 6U Wall Mount - Vented Door

- 6U Swing Out Wall Mount - Glass Door

- 6U Swing Out Wall Mount - Solid Door

- 6U Swing Out Wall Mount - Vented Door

- 9U Wall Mount - Glass Door

- 9U Wall Mount - Vented Door

- 9U Wall Mount - Solid Door

- 9U Swing Out Wall Mount - Glass Door

- Network Rack & Cabinet Shelves

- Hardware, Fans, and Accessories

- Rack Mount Cable Management Panels

- Wireless Access Points

- Cable Wraps, Straps, and Ties

- back

- Pre-Cut Hook & Loop Velcro Cable Ties

- back

- 6" x 1/2" Velcro Cable Ties - 25 pcs

- 6" x 1/2" Velcro Cable Ties - 100 pcs

- 6" x 1/2" Velcro Cable Ties - 1200 pcs

- 8" x 1/2" Velcro Cable Ties - 25 pcs

- 8" x 1/2" Velcro Cable Ties - 100 pcs

- 8" x 1/2" Velcro Cable Ties - 900 pcs

- 12" x 1/2" Velcro Cable Ties - 25 pcs

- 12" x 1/2" Velcro Cable Ties - 100 pcs

- 12" x 1/2" Velcro Cable Ties - 600 pcs

- 18" x 1/2" Velcro Cable Ties - 25 pcs

- 18" x 1/2" Velcro Cable Ties - 100 pcs

- 18" x 1/2" Velcro Cable Ties - 400 pcs

- 8" x 1/2" Cable Ties - 10 pcs w/Screw Mount

- Bulk Roll Velcro Cable Strap

- Wall Mount Velcro Cable Straps

- Fire Retardant Hook & Loop Cable Ties

- back

- 8" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 8" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 8" x 1/2" Velcro Ties - 900 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 600 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 400 pcs

- 75 Ft x 1/2" Roll Velcro Cable Wrap Strap

- Economy Velcro Cable Ties

- Cable Bundle Socks

- Clip-On Velcro Cable Carrier

- TV & LCD Screen Mounts

- back

- Wall Mount TV/LCD Screen Mounts

- back

- 13" - 27" Screen w/ 10.4" Arm

- 13" - 42" Screen w/ 10.7" Arm

- 10" - 42" Screen w/ 7.5" Arm

- 10" - 42" Screen w/ 2.9" Arm

- 13" - 42" Screen w/ 14.3" Arm

- 26" - 47" Screen w/ 22.8" Arm

- 32" - 70" Screen w/ 18.4" Arm

- 37" - 80" Screen w/ 18.4" Arm

- 32" - 55" Screen

- 37" - 70" Screen

- 37" - 80" Screen

- XL 60" - 100" Screen

- Slim Fixed 32" - 55" Screen

- Fixed 32" - 55" Screen

- Fixed 37" - 70" Screen

- Ceiling Mount TV/LCD Screen Mounts

- NPT Pipe TV Ceiling Mounts

- back

- 1.5" NPT Pipe Mount 32" - 55" Screen

- 1.5" NPT Pipe Mount 23" - 42" Screen

- 1.5" Double Sided NPT Mount 32"-55"

- 1.5" NPT Mount 37"-70"

- Flat Ceiling Plate for 1.5" NPT Pipe

- Angled Ceiling Plate for 1.5" NPT Pipe

- 1.5" NPT x 34.4 Long NPT Pipe

- Adjustable NPT Pipe 1.5"D x 8.66-14.57"L

- 1.5" NPT Pipe Coupler

Login

Fiber Optic Cleaning Products

In this category you will find all the necessary products needed to clean your fiber optic connector endfaces. We offer fiber optic cleaning kits that include all the necessary fiber optic cleaning supplies all in one convenient carrying case. We have both standard fiber optic cleaning kits and military fiber optic cleaning kits which includes cleaning sticks designed to clean specialized connectors often seen in military fiber optic installations. Our CleanClickers provide a quick and easy way to clean fiber optic endfaces. CleanClickers allow you to clean your fiber optic connector by just pushing in the tool until it clicks. It includes a rotating cleaning cloth at the end of it. We also have cleaning cassettes which allow you to place the fiber optic connector on a cleaning cloth and roll it back and forth. Our fiber optic cleaning sticks allow you to spray fiber optic cleaning fluid into the stick and then you rotate the stick around your fiber optic ferrule. The stick includes cleaning cloth material inside of it. These tools are used in conjuction with our fiber optic cleaning fluid. We offer our fiber optic cleaning fluid in 3oz and 10oz spray bottles. We also have a variety of lint free clean wipes. These are the most basic and simple a simple way to clean connectors with the use of fiber optic cleaning spray. These are also used to wipe the acrylic off the optic glass when fusing splicing.

Show More

Why it is Important to Keep Fiber Optic Connectors Clean

One of the most overlooked aspects of fiber optic maintenance and troubleshooting is keeping the fiber optic connector endfaces clean. As we will discuss later in this article, a dirty fiber connection can either slow down or completely inhibit network traffic.

Keeping fiber connections clean is different from any other type of cleaning due to the relative sizes of the connectors compared to the particles and contaminants that typically reside on them. Also we need to be diligent in their maintenance by cleaning the connectors every time before they are mated and after each un-mating. Static charges attract dust to the fiber connectors and prevent them from falling off even when blown with a can of compressed air. As we will see later on in this article, dust caps are primarily used to protect the ferrule and do not offer fail safe protection from particle matter. In some cases, the dust caps can actually make a clean connector dirty due to their tendency to keep a static charge. In addition to dust, there are other contaminants like dried liquid compounds that need to be dealt with on the cleanings.

When troubleshooting fiber, it is important to remember that dirty fiber connections can easily cause a slowdown or a complete shutdown of data traffic. An important tool for a network manager to have is a 200 or 400 power microscope. Dirty fiber connections should not be overlooked when troubleshooting fiber. CAUTION: Never look directly into an illuminated fiber. Laser light can cause permanent eye damage.

Frequently Asked Questions:

Q1: We know that dirty connections can cause attenuation. Can the dirty connections can also cause bit errors and/or slowdown of the network?

Yes, dirty connectors will cause Bit Errors because the contamination degrades the signal quality. In optical networks, the signal comes in the form of a beam of light travelling through the fiber’s core. The fiber’s core has a refractive index value of N1. When the light beam comes into contact with end face contamination, it is now coming entering a second medium which has different refractive index value which we will call N2. The signal experiences changes to both reflection and fraction as it enters the second medium. The signal is basically travelling down the fiber core as a sine wave. The contamination changes that sine wave by reducing the amplitude of the sine wave and spreading its wavelength because of the reflection and fraction that happens when the signal enters the second medium or N2. If you remove the contamination, you keep the light signal in the first N1 medium as it passes between connector 1 to connector 2 eliminating bit error rates.

Q2: Can dirt get between two fibers that are mated if left in a dusty environment? Or will the mating of the connectors prevent any dust from getting on the endfaces?

You do not have to worry about dust nor residue contaminate migration with physical contact connectors as long as they were cleaned before the mating process. The contact region between two mated single fiber connectors is diameter between 250μm to 200μm. When the two ferrules are physically mated, the mating force for most single fiber industry standard connectors is around 1kg or about 2.2lbs. If you calculate the force of what 2.2lbs in a 200μm, that comes to 45,000psi which is why contaminate migration is not a problem even in a dusty environment.

The best way to avoid any chance of contaminate migration is to use a wipe for cleaning unmated connectors on a cable assembly and a stick cleaner for connectors residing in an adapter. The mechanical cleaning tools like the One Click –style cleaners have a limited contact region and will never be able to clean the connector’s end face. The reason is the cleaning tip of a mechanical cleaner have to be able to rotate within the adapter sleeve without getting the cleaning strand or ribbon snagged on the split adapter sleeves. Stick cleaners do not have this problem and offer the largest effective cleaning region. Most cleaning sticks use a different type of cleaning material than the mechanical cleaners are not vulnerable to the snag problems of a flowing cleaning strand in the tools. The stick cleaners are rotated in the adapter sleeve as it cleans the mated connector’s end face. The contact the stick’s cleaning tip makes with the interior of the adapter sleeve during the rotation is helping to pull away dust and connector wear debris that was residing on the interior of the adapter sleeve. This help prevents future particle migration which could land on the ferrule end faces during the mating process.

There is an exception which are the expanded beam contacts. Expanded beam based connectors are starting to gain popularity in enterprise applications because of the Intel MXC connector and in Mil/Aerospace with lens connectors. The connector manufacturers explain that contamination is not a problem because the signal collimates into a large spot size as it passes from the lens of connector A to connector B. An end user would be wise to think about the environment his connectors are being exposed to before assuming he will never have to clean. A large enough piece of dust particulate residing somewhere on either lens will create problems. Also residues have different index of reaction and the amount of residue and its reflective characteristics will cause problems especially at higher data rates. The best practice to avoid long term problems and extend the life of your optical assemblies is to always inspect and remove any contamination regardless of the connector type.

Q3: Is it possible that an end cap (dust cap) can get dirty and cause the fiber endface to get dirty. Should you always clean a fiber when you remove the dust cap, prior to insertion onto a mating sleeve to connect the two fibers?

End caps are c common source of contamination when working with optical connectors. The connector end cap’s primary purpose is to protect the ferrule end face from scratch and pitting defects. It does not protect the ferrule end face from contamination. A customer should never assume that a capped cable assembly is clean when taken out of the bag. Dust and mold release agents are two common contaminates found in end caps.

If a customer gets a new jumper from the manufacturer and inspects it after taking the end caps off, it would not be uncommon to see some small amount of on contamination on the end d face. This does not mean that the jumper manufacturer’s quality process are lacking. All manufacturers experience this. The customer just needs to work smartly and realize that the end cap is just for protecting against scratches. The best practice is to inspect the ferrule, clean if necessary and re-inspect before mating. If the customer does not have a ferrule scope available, then cleaning both connectors end faces before mating will significantly reduce the likelihood of damage and cross contamination.

Q4: Please describe why “wet/dry” cleaning is better that simply either wet or dry cleaning alone.

There are two distinct advantages a wet-dry cleaning process has over the dry wipe process. The first is static dissipation and the second is the cleaning solvent’s ability to loosen up harden contaminates from the ferrule end face without causing permanent defects to the end face.

The dry wiping process that an operator would do using a Cletop style cassette or One Click style cleaner relies on contact friction to remove contamination. When two materials are rubbed together, there is a transfer of electrons between the two surfaces and the imbalance on the surface creates a charged electric force we call static electricity. The two surfaces, one charged positive and the other negative, will try to pull in surrounding particles to being the charge back into a neutral balance. This attraction pulls in the dust particulates in the air and the wear debris on the connector body and adapter. Fiber optic connectors are all dielectric and when they become charged by dry wiping a ferrule act as an insulator storing the electrical charge because there is no dissipative medium for the charge to flow off to. The problem with charged end faces become greater in in low humidity environments. The introduction of a cleaning solvent during a wet-dry cleaning process introduces static dissipative medium for the charge so that it does not stay on the ferrule surface.

Connectors that have been exposed to medium to severe levels of contamination benefit from the introduction of a cleaning fluid. The cleaning fluid will dissolve the harden contamination on a ferrule end face and loosen it up to be wiped away. Dry cleaning only of hardened contamination may require additional pressure by the operator which frequently leads to surface scratches causing permanent end face defects.

So we have seen that dirt or other contaminants that reside on fiber optic connector endfaces can cause major problems for the network. Dirt can even cause a slowdown that may not be apparent. And so it is wise for the network manager to have a microscope and fiber optic cleaning kit on hand for inspection and cleaning. If you are diligent with keeping all of the connections clean, you will avoid problems and have a fast running network.

Superior Customer Service // Free Technical Support // Fast Lead Times

888-568-1230

888-568-1230