Free shipping on orders over $250 Use code SHIP4FREE

Free shipping on orders over $250 Use code SHIP4FREE

Fast Lead Times | Fast Shipping

- Pre-Terminated Fiber Optic Assemblies

- back

- In Stock Pre-Terminated

- Indoor Plenum

- Indoor / Outdoor

- Indoor Plenum Interlock Armor

- Indoor Ultra Thin Armored

- I/O Plenum Interlock Armor

- Indoor / Outdoor Ultra Thin Armored

- Outdoor SST Drop Self Supporting

- Outdoor Loose Tube (OSP)

- Outdoor Gel Filled (OSP)

- Outdoor Ultra Thin Armored (OSP)

- Outdoor Armored Direct Burial (OSP)

- Outdoor Aerial with Messenger (OSP)

- Tactical and Rugged Deployable

- back

- Multimode OM3 Tactical

- Multimode OM4 Tactical

- Singlemode Tactical

- OpticalCON Tactical

- back

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber SM - Broadcast Tactical

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber SM - Broadcast Tactical

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber SM - Broadcast Tactical

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO SM Inline Coupler

- DUO OM3 Inline Coupler

- DUO APC Inline Coupler

- OpticalCON MTP 12 Chassis Connector

- 2 Port D-Series Wall Plate

- 1 Port D-Series Wall Plate

- HMA Expanded Beam Tactical

- back

- 2 Channel/Fiber

- 4 Channel/Fiber

- Ex. Beam 2 CH/F MM OM3 Chassis Conn.

- Ex. Beam 4 CH/F MM OM3 Chassis Conn.

- 4 CH to 2 X 2 CH OM3 Ex. Beam

- 2 CH OM3 Ex. Beam to OpticalCON Duo

- 4 CH OM3 Ex. Beam to OpticalCON Quad

- 4 CH OM3 Ex. Beam to 2 x OpticalCON Duo

- Ex. Beam Color Coding Ring

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Ex. Beam 1 CH/F MM OM3 Rotary Joint

- Ex. Beam 2 CH/F MM OM3 Conn. Mod.

- Ex. Beam 4 CH/F MM OM3 Conn. Mod.

- Mil-Tac Tactical Assemblies

- Neutrik® OpticalCON®

- back

- OpticalCON DUO

- back

- 2 Fiber SM - Broadcast Tactical

- 2 Channel SM - Mil-Tac Extreme

- 2 Fiber SM Hybrid SMPTE

- 2 Fiber OM3 - Broadcast Tactical

- 2 Fiber OM3 - Mil-Tac Extreme

- 2 Fiber SM - Tactical Patch Cable

- 2 Fiber OM3 - Tactical Patch Cable

- SM Duo to 2 Simplex Breakout Assembly

- OM3 Duo to 2 Simplex Breakout Assembly

- DUO Chassis Connector

- DUO Chassis Connector

- Neutrik D-Series Patch Panel

- DUO OM3 Inline Coupler

- DUO SM Inline Coupler

- DUO APC Inline Coupler

- 1 Port D-Series Wall Plate

- OpticalCON QUAD

- back

- 4 Fiber SM - Broadcast Tactical

- 4 Fiber SM - Mil-Tac Extreme

- 4 Fiber OM3 - Broadcast Tactical

- 4 Fiber OM3 - Mil-Tac Extreme

- 4 Channel SM Lite Tac Patch

- 4 Fiber OM3 - Tac Patch Cable

- SM Quad to 4 Simplex Breakout Assembly

- OM3 Quad to 4 Simplex Breakout Assembly

- QUAD Chassis Connector

- Neutrik D-Series Patch Panel

- QUAD OM3 Inline Coupler

- QUAD SM Inline Coupler

- QUAD APC Inline Coupler

- SHUTTER BUDDY

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- OpticalCON MTP

- back

- 12 Fiber SM - Broadcast Tactical

- 12 Fiber SM - Mil-Tac Extreme

- 12 Fiber OM3 - Broadcast Tactical

- 12 Fiber OM3 - Mil-Tac Extreme

- 12 Channel MTP SM Lite Tac Patch

- 12 Fiber OM3 - Tac Patch Cable

- SM MTP to 12 Simplex B/O Assembly

- OM3 MTP to 12 Simplex B/O Assembly

- OpticalCON MTP 12 Chassis Connector

- Neutrik D-Series Patch Panel

- OM3 Multimode Inline Coupler

- Singlemode APC Inline Coupler

- 1 Port D-Series Wall Plate

- 2 Port D-Series Wall Plate

- Hybrid Fiber + Power

- MTP Trunk Cables, Fanouts, & Cassettes

- back

- Indoor MTP Trunks

- Indoor/Outdoor MTP Trunks

- Indoor Armored MTP Trunks

- In/Outdoor Armored MTP Trunks

- Outdoor Loose Tube MTP Trunks

- Outdoor Self Sup. Drop MTP Trunks

- Outdoor Micro Armored MTP Trunks

- Outdoor Armored MTP Trunks

- IP68 Weatherproof OptiTip® HMFOC

- Stock Indoor MPO Cables

- Stock In/Outdoor MTP/MPO Trunks

- Indoor MTP Fanouts

- back

- Multimode OM3 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Multimode OM4 50/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- Singlemode 9/125

- back

- 1 x 12 MTP to 12 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- 6 x 12 MTP to 72 Simplex Connectors

- 8 x 12 MTP to 96 Simplex Connectors

- 12 x 12 MTP to 144 Simplex Connectors

- 1 x 24 MTP to 24 Simplex Connectors

- 2 x 24 MTP to 48 Simplex Connectors

- 3 x 24 MTP to 72 Simplex Connectors

- 4 x 24 MTP to 96 Simplex Connectors

- 6 x 24 MTP to 144 Simplex Connectors

- 2 x 12 MTP to 24 Simplex Connectors

- 4 x 12 MTP to 48 Simplex Connectors

- Indoor / Outdoor MTP Fanouts

- MTP OSP Loose Tube Fanout Cable

- MTP OSP Armored Fanout Cable

- Stock Indoor MPO Fanout Cables

- Cassettes and Components

- back

- OM3 Cassettes

- OM4 Cassettes

- Singlemode Cassettes

- Enclosures

- back

- Super High Density 5 panel (1U)

- Super High Density 14 panel (2U)

- Lightweight Aluminum 2 panel (1U)

- Lightweight Aluminum 3 panel (1U)

- Lightweight Aluminum 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 2 Panel (1U)

- Multilink 3 panel (1U)

- Multilink 4 panel (2U)

- Multilink 6 panel (2U)

- Multilink 12 panel (2U)

- 4 panel (1U) UHD Patch Panel

- Couplers and Adapter Panels

- MTP/MPO to LC LGX Cable Harness

- Fiber Patch Cables, Enclosures, & Couplers

- back

- Fiber Enclosures & Adapter Panels

- back

- Rack Mount Termination Boxes

- back

- Lightweight Aluminum 2 panel (1U)

- Multilink 2 Panel (1U)

- 2 panel (1U) Slide Out 16 AWG

- Lightweight Aluminum 3 panel (1U)

- 3 panel (1U) Swing Out Splice Box

- 3 panel (1U) LGX Patch Panel

- Multilink 3 panel (1U)

- 3 panel (1U) Slide Out 16 AWG

- 4 panel (1U) UHD Patch Panel

- Lightweight Aluminum 4 panel (2U)

- Multilink 4 panel (2U)

- Lightweight Aluminum 6 panel (2U)

- Multilink 6 panel (2U)

- Lightweight Aluminum 12 panel (4U)

- Multilink 12 panel (2U)

- Super High Density 5 panel (1U)

- Wall Mount Termination Boxes

- back

- QuickTreX 2 Adapter / 1-4 Fiber

- Lightweight Aluminum 1 panel

- Heavy Duty Steel 1 panel

- Multilink 1 Panel

- Multilink 1 Panel w/ Splice

- Lightweight Aluminum 2 panel

- Multilink 2 Panel

- Lightweight Aluminum 4 panel

- Multilink 4 Panel

- Multilink 4 Panel with Splice

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- Outdoor Harsh Environment

- back

- QuickTreX 1 Adapter / 1-2 Fiber

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 1 Panel Splitter/Splice Enclosure

- Multilink 2 Panel Outdoor

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- QuickTreX 12 Fiber Splice

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- Multimode OM1 Adapter Panels

- Multimode OM2/3/4 Adapter Panels

- Multimode OM5 Adapter Panels

- Singlemode Adapter Panels

- back

- QuickTreX 12 Fiber LC UPC

- QuickTreX 12 Fiber LC APC

- Multilink 12 Fiber LC UPC

- Multilink 12 Fiber LC APC

- QuickTreX 24 Fiber LC UPC

- QuickTreX 24 Fiber LC APC

- Multilink 24 Fiber LC UPC

- Multilink 24 Fiber LC APC

- QuickTreX 6 Fiber SC UPC

- QuickTreX 6 SC APC

- QuickTreX 12 Fiber SC UPC

- QuickTreX 12 Fiber SC APC

- Multilink 6 Fiber SC UPC

- Multilink 6 Fiber SC APC

- Multilink 12 SC UPC

- Multilink 12 SC APC

- MTP Adapter Panels

- Blank Adapter Panels

- Splice Trays

- Custom Fiber Optic Patch Cables

- Custom Armored Fiber Patch Cables

- Stock Tactical Fiber Patch Cables

- back

- Stock Tac SM - Duplex LC UPC - 100FT

- Stock Tac SM - Duplex LC APC - 100FT

- Stock Tac SM - Duplex SC APC - 100FT

- Stock Tac SM - Duplex SC UPC - 100FT

- Stock Tac SM - Simplex LC UPC - 100FT

- Stock Tac SM - Simplex SC UPC - 100FT

- Stock Tac SM - Simplex SC APC - 100FT

- Stock Tac SM - Simplex LC APC - 100FT

- Stock Duplex Fiber Patch Cables

- Stock Uniboot Fiber Patch Cables

- Stock Simplex Fiber Patch Cables

- Fiber Optic Couplers & Attenuators

- back

- Multimode OM1 62.5/125

- back

- LC Simplex w/ Flange

- LC Duplex w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Simplex w/ Flange and Hinged Door

- LC Quad w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM3/4 50/125

- back

- LC Duplex w/ Flange

- LC Quad w/o Flange

- LC Quad w/ Flange

- SC Simplex w/o Flange

- SC Simplex w/ Flange

- SC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/o Flange

- FC Simplex - Universal MM/SM w/o Flange

- ST Simplex - Universal MM/SM w/Flange

- MPO Coupler - MM OM3 / OM4 Aqua

- ST Duplex - Universal MM/SM w/Flange

- Multimode OM5 50/125

- Singlemode

- back

- LC UPC Simplex w/o Flange

- LC APC Simplex w/o Flange

- LC UPC Duplex w/ Flange

- LC APC Duplex w/ Flange

- LC UPC Quad w/o Flange

- LC APC Quad w/o Flange

- SC UPC Simplex w/ Flange

- SC UPC Simplex w/o Flange

- SC UPC Simplex w/ Flange and Hinged Door

- SC APC Simplex w/ Flange

- SC APC Simplex w/o Flange

- SC APC Simplex w/ Flange and Hinged Door

- SC UPC Duplex w/ Flange

- SC APC Duplex w/ Flange

- ST Simplex - Universal MM/SM w/Flange

- ST Simplex - Universal MM/SM w/o Flange

- Keystone Couplers & Accessories

- back

- LC Duplex MM OM1 - Ivory

- LC Duplex MM OM3 / 4 - Aqua

- LC Duplex MM OM5 - Lime Green

- LC UPC Duplex SM - Blue

- LC Duplex SM APC - Green

- SC Simplex MM OM1 - Beige

- SC Simplex MM OM3 / 4 - Aqua

- SC UPC Simplex SM - Blue

- SC APC Simplex SM - Green

- MTP Singlemode

- MTP Multimode OM3/4

- Gloss Finish Keystone Wallplates

- Easy Wallplate Bracket

- 12 Port - 1U

- 6 Port LGX Blank Keystone Adapter Panel

- MTP / MPO Couplers

- Optical Attenuators

- Fiber Optic Splitters

- Mode Conditioning Fiber Cables

- Bulk Fiber Optic Cable, Testing, & Cleaning

- back

- Unterminated Fiber Optic Cable

- Fiber Optic Pigtail Kits

- back

- OM1 62.5/125 Multimode

- OM3 50/125 Multimode

- OM4 50/125 Multimode

- OM5 50/125 Multimode

- Singlemode

- back

- 1 meter LC 6 Fiber

- 3 meter LC 6 Fiber

- 3 meter SC 6 Fiber

- 1 meter ST 6 Fiber

- 3 meter ST 6 Fiber

- 1 meter LC 12 Fiber

- 3 meter LC 12 Fiber

- 3 meter LC APC

- 3 meter LC 12 Fiber Ribbon

- 3 meter SC APC 12 Fiber

- 3 meter SC 12 Fiber

- 3 meter SC UPC 12 Fiber Ribbon

- 1 meter ST 12 Fiber

- 3 meter ST 12 Fiber

- 2 meter LC 1 Fiber

- 2 meter SC 1 Fiber

- Fiber Optic Splice Trays & Boxes

- back

- Fiber Optic Splice Enclosures

- back

- Multilink 2 Panel Outdoor

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 480 Splice Dome Enclosure

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 1 Panel Splitter/Splice Enclosure

- Multilink 1 Panel w/ Splice

- Multilink 4 Panel with Splice

- Lightweight Aluminum 1 panel

- 3 panel (1U) Swing Out Splice Box

- QuickTreX 12 Fiber Splice

- Fiber Optic Splice Trays

- Fiber Optic Supplies & Tools

- Fiber Optic Cleaning Products

- Fiber Optic Test Instruments

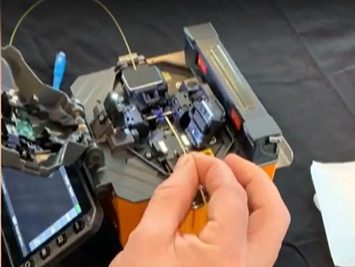

- Fusion Splicers and Accessories

- Fiber Optic Loopback Testers

- Fiber Optic Mounting Hardware

- Fiber Optic Reference Cable Kits

- Ethernet Patch Cables, Bulk Cable, & Accs.

- back

- Ethernet Patch Cables

- back

- Tactical & Rugged Deployable

- back

- Cat 5E Shielded - Custom Length

- Stock 40FT Cat 5E Shielded

- Cat 6A Shielded - Custom Length

- Stock 30FT Cat 6A Shielded

- RJ45 etherCON Coupler

- RJ45 etherCON Coupler w/ Sealing Kit

- RJ45 Cat 6A etherCON Coupler - Black

- Cat 6A etherCON Coupler - Nickel

- Neutrik D-Series Patch Panel

- Cat 6 Outdoor Inline

- Cat 6A Outdoor Panel Mount w/Cap

- Cat 6A Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- Cat 5E Custom Made in the USA

- Cat 5E Stock

- Cat 6E Custom Made in the USA

- Cat 6 Stock

- Cat 6A Custom Made in the USA

- Cat 6A Stock

- Cat 6A Stock Outdoor Armored

- Stock Cat 6A Shielded Tactical

- Outdoor Custom Made in the USA

- Cat 6 Outdoor

- Cat 8 Custom Made in the USA

- Cat 7 Stock

- Cat 8 Stock

- 110 Cat 5 Custom Patch Cables

- Custom Cable Bundles

- Bulk Ethernet Cable

- back

- Cat 5e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, Riser (CMR), Solid, 1000 ft

- 24AWG Solid Riser , 1000 ft

- Plenum Rated Solid 1000FT USA Made

- Solid Plenum 1000FT

- 24AWG Solid Plenum, 1000 ft

- Direct Bury, CMX, Solid, 1000 ft

- 24 AWG Direct Burial Solid, 1000 ft

- 24 AWG Outdoor DB 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 5E Shielded

- Cat 6 / 6e Unshielded

- back

- PVC, (CM), Stranded, 1000ft

- PVC, 28 AWG Stranded, 1000 ft

- PVC Riser (CMR), Solid, 1000 ft

- 23AWG Solid Riser (CMR), 1000 ft

- Plenum (CMP), Solid, 1000 ft

- 23AWG Solid Plenum (CMP), 1000 ft

- Outdoor DB Solid 1000FT USA Made

- Direct Burial, CMX, Solid, 1000 ft

- Outdoor w/Messenger 1000FT USA Made

- Cable Reel Deployment Caddy

- Cat 6 / 6E Shielded Bulk Cable

- Cat 6A Unshielded

- Cat 6A Shielded

- Cat 7A Shielded

- Cat 8 Shielded

- Data & Voice Connectors

- back

- Keystone Jacks

- back

- Cat 5E - 90° Punch Down

- Cat 5E - 180°Punch Down

- Cat 6 - 90° Punch Down

- Cat 6 - 180° Punch Down

- Cat 6 Shielded 90° Punch Down

- Cat 6A - 90° Punch Down

- Cat 6A Shielded 90 Degree

- Cat 6A Shielded -180° Toolless

- Cat 8 Shielded - 90° Toolless

- Cat 8 Shielded - 90° Toolless w/Door

- RJ-11/12 Voice - 90° Punch Down

- Keystone Couplers

- Modular Plugs

- back

- Cat 5E UTP - 100 pcs USA Made

- Cat 6/6E UTP - 100 pcs USA Made

- Cat 5E/6E STP - 50 pcs USA Made

- Cat 5E/6E STP - 10 pcs USA Made

- Cat 6A STP - 50 pcs USA Made

- Cat 6A STP - 10 pcs USA Made

- Cat 8 STP - 10 pcs

- Cat 8 STP - 25 pcs

- Cat 8 STP Toolless

- Cat 6A UTP - 100 pcs

- Cat6 UTP Feed Through - 100 pcs

- Cat 6 STP Feed Through - 100 pcs

- Strain Relief Boots

- Wallplates and Surface Mount Boxes

- Splitters

- Coaxial F Connectors

- Ethernet Patch Panels

- Datacom Tools and Testers

- back

- Data & Voice Tools

- back

- PRO RJ-45 Crimper

- PRO Large OD Crimper

- Hex Crimper

- Economy RJ-45 Crimper

- PRO 110 Impact Termination Tool

- 110 Replacement Blade

- 66 Replacement Blade

- EZ RJ45 Keystone Jack Crimper

- Economy Termination Tool

- Wire and Kevlar Scissors

- Large OD Cable Stripper & Cutter

- UTP & STP Cable Stripper

- Electrical Wire Stipper

- Coaxial Cable Cutter

- Conductor Separator & Straightener

- QuickTreX Premium Adjustable Hat

- Test Equipment

- Cable Installation

- Coaxial CATV Tools

- Hand Tools

- Cable Reels

- Bulk Coaxial, Audio, and Power Cable

- back

- Co-ax RG-6 Shielded Bulk Cable

- back

- Dual Shield CCS Riser, 1000 ft WT

- Quad Shield CCS Riser, 500 ft BK

- Quad Shield CCS Riser, 1000 ft BK

- Quad Shield CCS Plenum, 1000 ft WT

- Quad Shield Solid Copper Plenum, 1000

- Dual Shield Direct Burial CCS, 1000 ft BK

- Quad Shield Direct Burial CCS, 1000 ft BK

- RG6 F Male Compression 10 Pack

- Cable Reel Deployment Caddy

- Composite Cable & Cable Bundles

- Power Cable Bulk

- Thermostat Bulk Cable

- back

- 18/2 Riser Rated, Solid Copper PVC, 500 ft

- 18/3 Riser Rated, Solid Copper PVC, 500 ft

- 18/4 Riser Rated, Solid Copper PVC, 500 ft

- 18/5 Riser Rated, Solid Copper PVC, 500 ft

- 18/6 Riser Rated, Solid Copper PVC, 500 ft

- 18/8 Riser Rated, Solid Copper PVC, 500 ft

- 20/2 Riser Rated, Solid Copper PVC, 500 ft

- 20/5 Riser Rated, Solid Copper PVC, 500 ft

- 20/8 Riser Rated, Solid Copper PVC, 500 ft

- Cable Reel Deployment Caddy

- Audio Cable Bulk

- IT Technician Tool Kits and Cases

- RJ45 Dust Plugs, Caps, and Locks

- Cable Mounting Hardware

- HDMI Cables

- Power Cords and Supplies

- Harsh Environment Cables, FTTA, RF, & IP68

- back

- OptiTip, OptiTap, HMA, & FTTA

- RF Cable Assemblies

- RF Connectors & Adapters

- back

- RF Connectors

- back

- Mini-UHF Male Crimp

- Mini-UHF Male Crimp RG-58/U

- UHF Male Solder

- UHF Male Crimp

- M Male Crimp

- N Male Crimp 50 ohm

- N Male Crimp G,G,T, 50 ohm

- N Male Crimp For Cable Group X S,G,T

- N Male Crimp RG-142/U & RG-55/U

- N Male Crimp for Cable Group B N,G,T

- SMA Male Crimp

- SMA Male Crimp RG-8/X

- SMA Male Crimp for Cable Group B N,G,T

- BNC Male Crimp RG58/U

- TNC Male Crimp RG-58/U

- TNC Male Crimp RG-8X

- RF Adapters

- Harsh Env. Fiber Optic Assemblies

- Toolkits, Cases & Enclosures

- back

- Termination Boxes

- back

- Multilink 2 Panel Outdoor

- 4 panel Outdoor NEMA Enclosure

- Dome Pedestal Enclosure

- QuickTreX 2 Adapter / 1-4 Fiber

- QuickTreX 8 Adapter / 1-16 Fiber

- QuickTreX 16 Adapter w/Splice - IP65

- QuickTreX 6 Panel Steel w/Splice

- QuickTreX 24 Adapter w/Splice - IP65

- QuickTreX 1 Panel Splitter/Splice Enclosure

- QuickTreX 1-36F Aerial/Wall Splice/Splitter Box

- QuickTreX 144 Fiber Aerial Splice Enclosure

- QuickTreX 480 Splice Dome Enclosure

- Network IT Toolkits

- Network IT Tool Cases

- Ethernet Patch Cables & Bulk Cable

- back

- Copper Cables and Assemblies

- Bulk Outdoor Copper Cable

- Outdoor Patch Cables

- Outdoor Accessories

- back

- Cat 6 Outdoor Panel Mount

- Cat 6 Outdoor Panel Mount w/Cap

- Cat 6 Shielded Outdoor Panel Mount

- Cat 6 Shielded Outdoor Panel Mount w/Cap

- Outdoor Patch Cable Cap

- 1 Gang Outdoor Wallplate

- Water-Resistant 1 Gang

- 1 Port (1 Gang) Stainless Steel Keystone Wall Plate for Mounting RJ45 Keystone Connectors and Couplers

- Network Switches, SFPs, Converters, & Racks

- back

- Network Switches

- back

- Unmanaged Gigabit

- Managed Gigabit

- Unmanaged Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 4xRJ45,1xRJ,1xSFP

- QuickTreX 12 Port GIG w/ 8xRJ45,2xRJUL,2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 2xSFP

- QuickTreX 48 Port GIG w/ 48xRJ45 & 2xSFP

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 16 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 4 Port Gigabit

- Managed Gigabit PoE

- back

- QuickTreX 8 Port GIG w/ 8xRJ45 & 2xSFP

- QuickTreX 24 Port GIG w/ 24xRJ45 & 4xSFP/RJ45

- QuickTreX 36 Port 10G UL w/ 24xRJ45, 8xSFP, 4xSFP+

- 8 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port Gigabit w/ 2 Gigabit SFP Ports

- 24 Port G w/ 4 x GIG SFP Ports + PoE Inj

- 24 Port Gigabit w/ 4 x 10Gigabit SFP Ports

- 24 Port Gigabit w/ 2 SFP Ports (Full Power)

- 24 Port Gigabit w/ 4 SFP+ Ports (Full Power)

- Unmanaged Industrial Switches

- Managed Industrial Switches

- Unmanaged Industrial PoE Switches

- back

- QuickTreX 6 Port GIG w/ 4xRJ45 & 2xSFP

- QuickTreX 10 Port GIG w/ 8xRJ45 & 2xSFP

- 4 Port Gigabit POE+ w/ 2 SFP Ports

- 4x10/100M TX PSE and 1x1000M SC MM

- 4x10/100M TX PSE + 1x10/100M

- 5 x RJ45 10/100/100BaseTX

- 5 x RJ45 1000Bast w/ 4 x Gig 30W PSE

- 8 x RJ45 10/100/1000m w/ v Boost

- 8 Port Gigabit POE+ w/ 2 SFP Ports

- 8 x Gig TX 30W PSE + 2 x 1000M TX/SFP w/ v Boost

- Managed Industrial PoE Switches

- Industrial Power Supplies

- SFP / QSFP Modules

- back

- Multimode SFP Modules

- Singlemode SFP Modules

- back

- 1.25 GIG - 2km at 1310nm by QuickTreX

- 10 GIG - 10km at 1310nm by QuickTreX

- 1F/BiDi Kit 1.25 GIG - 20km by QuickTreX

- 1.25 GIG - 20km at 1310nm by Unicom

- 1.25 GIG - 40km at 1310nm by Unicom

- 1.25 GIG - 80km at 1310nm by Unicom

- 1.25 GIG - 100km at 1310nm by Unicom

- 1.25 GIG - 120km at 1310nm by Unicom

- 1.25 GIG - 160km at 1310nm by Unicom

- 1.25 GIG - 180km at 1310nm by Unicom

- 10 GIG - 10km at 1310nm by Unicom

- 10 GIG - 40km at 1550nm by Unicom

- 10 GIG - 80km at 1550nm by Unicom

- 10 GIG - 100km at 1550nm by Unicom

- 10 GIG - 10km at 1310nm Cisco Compatible

- 1.25 GIG - 10km at 1310nm by Signamax

- Industrial SFP Modules

- back

- MM 1.25 GIG - 500 m / 850nm by QuickTreX

- SM 1.25 GIG - 20 km / 1310nm by QuickTreX

- MM 10 GIG - 300m / 850nm by QuickTreX

- SM 10 GIG - 10 km / 1310nm by QuickTreX

- MM GIG - 550m / 850nm by Signamax

- MM GIG - 2km / 1310nm by Signamax

- SM GIG - 10km / 1310nm by Signamax

- SM GIG - 40km / 1310nm by Signamax

- SM GIG - 40km / 1550nm by Signamax

- SM GIG - 80km / 1550nm by Signamax

- SM GIG - 110km / 1550nm by Signamax

- SM BiDI GIG - 10km 1310TX/1550RX

- SM BiDI GIG - 10km 1550TX/1310RX

- QSFP Modules

- Media Converters

- Network Racks and Cabinets

- back

- Free Standing Racks

- Open Frame Wall Rack

- back

- QuickTreX 16U (19"W x 18"D)

- Kendall Howard 8U (Adjustable W x 18"D)

- Kendall Howard 12U (Adjustable W x 18"D)

- Kendall Howard 12U Swing-Out

- Kendall Howard 18U Swing-Out

- Kendall Howard 12U Side Load

- Kendall Howard 12U (19"W x 12"D)

- Kendall Howard 16U (19"W x 12"D)

- Kendall Howard 12U (19"W x 18"D)

- Kendall Howard 16U (19"W x 18"D)

- Kendall Howard 2U Vertical w/ Tapped Rails

- Kendall Howard 4U Vertical w/ Tapped Rails

- Kendall Howard 2U Vertical

- Kendall Howard 4U Vertical

- Wall Mount Network Cabinets

- back

- QuickTreX 4U Swing-Out Hinged

- QuickTreX 4U Fixed

- QuickTreX 6U Swing-Out Hinged

- QuickTreX 6U Fixed

- QuickTreX 9U Swing-Out Hinged

- QuickTreX 9U Fixed

- QuickTreX 12U Fixed

- 6U Wall Mount - Glass Door

- 6U Wall Mount - Solid Door

- 6U Wall Mount - Vented Door

- 6U Swing Out Wall Mount - Glass Door

- 6U Swing Out Wall Mount - Solid Door

- 6U Swing Out Wall Mount - Vented Door

- 9U Wall Mount - Glass Door

- 9U Wall Mount - Vented Door

- 9U Wall Mount - Solid Door

- Network Rack & Cabinet Shelves

- Hardware, Fans, and Accessories

- Rack Mount Cable Management Panels

- Wireless Access Points

- Cable Wraps, Straps, and Ties

- back

- Pre-Cut Hook & Loop Velcro Cable Ties

- back

- 6" x 1/2" Velcro Cable Ties - 25 pcs

- 6" x 1/2" Velcro Cable Ties - 100 pcs

- 6" x 1/2" Velcro Cable Ties - 1200 pcs

- 8" x 1/2" Velcro Cable Ties - 25 pcs

- 8" x 1/2" Velcro Cable Ties - 100 pcs

- 8" x 1/2" Velcro Cable Ties - 900 pcs

- 12" x 1/2" Velcro Cable Ties - 25 pcs

- 12" x 1/2" Velcro Cable Ties - 100 pcs

- 12" x 1/2" Velcro Cable Ties - 600 pcs

- 18" x 1/2" Velcro Cable Ties - 25 pcs

- 18" x 1/2" Velcro Cable Ties - 100 pcs

- 18" x 1/2" Velcro Cable Ties - 400 pcs

- Bulk Roll Velcro Cable Strap

- Wall Mount Velcro Cable Straps

- Fire Retardant Hook & Loop Cable Ties

- back

- 8" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 8" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 8" x 1/2" Velcro Ties - 900 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 100 pcs

- 12" x 1/2" Velcro Hook & Loop Ties - 600 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 10 pcs

- 18" x 1/2" Velcro Hook & Loop Ties - 400 pcs

- 75 Ft x 1/2" Roll Velcro Cable Wrap Strap

- Economy Velcro Cable Ties

- Cable Bundle Socks

- Clip-On Velcro Cable Carrier

- TV & LCD Screen Mounts

- back

- Wall Mount TV/LCD Screen Mounts

- back

- 13" - 27" Screen w/ 10.4" Arm

- 13" - 42" Screen w/ 10.7" Arm

- 10" - 42" Screen w/ 7.5" Arm

- 10" - 42" Screen w/ 2.9" Arm

- 13" - 42" Screen w/ 14.3" Arm

- 26" - 47" Screen w/ 22.8" Arm

- 32" - 70" Screen w/ 18.4" Arm

- 37" - 80" Screen w/ 18.4" Arm

- 32" - 55" Screen

- 37" - 70" Screen

- 37" - 80" Screen

- XL 60" - 100" Screen

- Slim Fixed 32" - 55" Screen

- Fixed 32" - 55" Screen

- Fixed 37" - 70" Screen

- Ceiling Mount TV/LCD Screen Mounts

- NPT Pipe TV Ceiling Mounts

- back

- 1.5" NPT Pipe Mount 32" - 55" Screen

- 1.5" NPT Pipe Mount 23" - 42" Screen

- 1.5" Double Sided NPT Mount 32"-55"

- 1.5" NPT Mount 37"-70"

- Flat Ceiling Plate for 1.5" NPT Pipe

- Angled Ceiling Plate for 1.5" NPT Pipe

- 1.5" NPT x 34.4 Long NPT Pipe

- Adjustable NPT Pipe 1.5"D x 8.66-14.57"L

- 1.5" NPT Pipe Coupler

Login

MTP / MPO CABLE & CASSETTES

In this category we offer custom MTP trunk assemblies, MTP fanout assemblies, and MTP cassettes in multimode om3 and om4, and singlemode. We offer these assemblies in the following jacket types: indoor plenum, indoor/outdoor plenum rated, outdoor (OSP) loose tube, and outdoor armored direct burial rated. We also offer both our MTP trunk assemblies and MTP fanout assemblies with microarmor jacket. All of our MTP trunk and fanout assemblies are custom made to order is the usa and include corning glass and genuine us conec connectors. Our manufacturing process includes strict quality control and come fully tested with a test report. Our MTP cassettes are premium quality and include low loss and genuine us conec connectors. We also offer high density MPO cassettes for high strand count installations that require minimal rack space.

Show More

MTP/MPO Cable Polarity

Optical fiber networks require two fibers to make a complete circuit. The matching of the transmit Tx signal to the receive Rx equipment is referred to as polarity, and a transmit and receive side on optical transceivers usually use a duplex fiber connector to maintain the polarity. On most cabling systems, maintaining polarity just requires that the A side of one connector pair matches the B side of the other connector pair, with fiber connectors such as ST, LC, SC, and MTRJ.

MTP/MPO high density network design requires its own set of rules regarding maintaining polarity throughout the link. These three polarity methods are commonly referred to as Method A, Method B, and Method C, and we will discuss the difference further here. Come see why our MTP & MPO cables, cassettes, and components are second to none in the industry.

Method A – Straight Through

This type of MTP cable has a key up key down position, and the fiber remains the same straight through the cable. Therefore, each fiber is in the same position on each end of the cable. Fiber 1 in the cassette mates to Fiber 1 in the cable assembly, which mates to Fiber 1 in the end cassette. This type of MTP cable has a key up key down position, and the fiber remains the same straight through the cable. Therefore, each fiber is in the same position on each end of the cable. Fiber 1 in the cassette mates to Fiber 1 in the cable assembly, which mates to Fiber 1 in the end cassette.

The transmit/receive flip must happen with the patch cords either at the beginning or end of the link to ensure proper transceiver polarity.

Method B – Fully Flipped (1-12, 12-1)

This method utilizes a key up to key up position and this fiber cable is fully flipped on either end. This type of mating creates an inversion, where Fiber 1 is mated with Fiber 12, and Fiber 2 is mated with Fiber 11, etc. For these cables to preform properly, one of the cassettes would need to be inverted internally for Fiber 12 is mated with Fiber 1 at the end of the link. This method requires two different cassettes with special labeling to identify which one is flipped. This circuit is completed with using straight patch cords at the beginning and end of the link.

*Note- method B is not compatible with our standard QuickTrex cassettes.

Method C – Pair Flip

Method C and Method A are very similar, with the main difference being the flipping of the patch cords in the link. This method uses key up key down, and the polarity flip takes place within the cable itself. Each adjacent pairs of fiber at one end are flipped at the other end. So, Fiber 1 and Fiber 2 becomes Fiber 2 and Fiber 1 at the other end, and so on.

This circuit is completed by using straight patch cords at the beginning and end of the link.

MTP/MPO Connector Types

Although most people in the industry refer to this connector as MTP, it is actually correct to also call it MPO. The term MTP is a registered trademark of USConec and identifies their specific brand of the MPO-style connector.

The name MPO stands for Multifiber Push On, and typically consists of a 12 strand Ribbon Fiber that is terminated to a single compact push on connector. Our MTP & MPO cables, cassettes, components and connector types are available online now.

Male MTP/MTO Connector

The pins on the MTP/MPO connector signifies that is it a Male connector.

The white dot on the right, signifies position 1 on the MTP pinout.

The raised tab on the top of the connector signifies it is in the key up position.

Female MTP/MTO Connector

The lack of pins on the MTP/MPO connector signifies that it is a Female connector.

The white dot on the right, signifies position 1 on the MTP pinout.

The raised tab on the top of the connector signifies it is in the key up position.

MTP Strand Counts

There are three popular MTP strand counts available on the market today.

The MTP 8 Connector utilizes 8 of the 12 fibers in a standard 12 Fiber Connector. QSFP applications use the outer four fiber spots (1 – 4 and 8-12) of the MTP connector with four fibers used to transmit and four to receive. Method B is the most commonly used polarity method for a MTP 8.

The MTP 12 Connector is the most popular choice for a MTP connector and is recognized as industry standard. Method A, B, and C are available in a MTP 12. Method A is the recommended polarity method.

The MTP 24 is the most cost effective and high-density solution for MTP, as this connector is able to harness 24 fiber strands in one connector. There are various polarity options for MTP 24, but Method A is recommended, and is standard on our QuickTreX assemblies.

Connecting MTP Connectors

When connecting, or mating, two MTP connectors together, you will need an MTP adapter to accomplish this. The male connector should be in the key up position, and the female in the key down position.

MTP Cassettes

Maintaining proper polarity across your network is also applicable when choosing a cassette. Cassettes come in a few different forms: 12 Fiber (1 x 12), 24 Fiber (2 x 12), and 24 Fiber (1 x 24). It is especially important to make sure the MTP configuration on your MTP Trunk Assembly or MTP Fanout Assembly is compatible with the MTP Cassette you choose.

Cassettes will be labeled as Method A/C or Method B. The main difference here is orientation of the way the MTP cables are mated together. Alignment pins are pre-installed in the MTP/MPO connector located inside the cassette. These pins precisely align the mating fibers in the MTP/MPO connectors at either end of the cables that plug into the cassettes.

For Method A or Method C Polarity:

Method-A cassettes make a key up to key down connection between the internal MTP connector and the MTP cable connector.

The cassettes will already be in a key up position, and when plugging in your MTP connector it needs to be in the key down position.

For Method B Polarity:

Method-B cassettes make a key up to key up, key down to key down connection. For these cables to perform properly, one of the cassettes would need to be inverted internally for Fiber 12 is mated with Fiber 1 at the end of the link. This method requires two different cassettes with special labeling to identify which one is flipped.

One cassette will be in the key up position, with the MTP cable also being key up.

One cassette will be in the key down position, with the MTP cable also being key down.

Method B cassettes are not recommended for Singlemode APC fiber applications, because the angles of the mating connectors do not line up properly with this configuration and are not sufficient for low loss applications.

*QuickTreX cassettes support a method A/C configuration, and are not compatible with Method B.

Method B in Parallel Optics

Method B polarity is particularly useful in regard to 40G parallel optic applications, and direct switch to switch connectivity. Method B MTP cables are also referred to as a QSFP/QSFP+ cable or direct attach 40GBASE-SR4, 40GBASE-PLR4 or 40GBASE-PLRL4. This orientation is useful because instead of an alternating Tx to Rx duplex pattern, 40G parallel optics utilizes the flipped Pin 1 to Pin 12, Pin 12 to Pin 1 pinout.

Female to Female type B trunk cables can also be used for a direct switch to switch connectivity going directly into 40G transceivers, or with an MTP adapter, used to connect a patch panel to a QSFP+ transceiver.

Completing the Link

We have talked about the different types of MTP polarities, and how to properly mate two MTP connectors. The last step in a standard MTP application is breaking out the high-density fiber strands into standard fiber connectors.

If you are using a cassette, then you will need standard fiber jumper cables to complete the polarity methodology. If you are using an adapter, then you will be connecting the MTP trunk cable to an MTP Fanout Assembly which will have standard fiber connector fanouts. The MTP Fanout Builder will go into more depth on configuration there, so let’s focus on a MTP cassette method with patch cables.

There are two types of duplex fiber patch cables as defined in the TIA standard: A to A, and A to B. Maintaining proper polarity requires the B Tx signal to connect to the A Rx signal.

A to B patch cables are also known as “straight-through”

A to A patch cables are also known as “flipped”

Patch cords made with individual single fiber connectors at each end allow the flexibility for connections to be “swapped” when a polarity reversal is required. Our QuickTreX Custom USA fiber optic patch cables will provide the ability to be swapped.

MTP Accessories

MTP Coupler

An MTP coupler is used to connect two 12 fiber MTP male to MTP female connectors together.

MTP Adapter Panel

This can also be accomplished using an MTP adapter panel which will have 6 or 8 MTP/MTO couplers within the panel. This is useful to connect an MTP assembly with an MTP Fanout cable - Male to Female Connections

MTP Cassette

MTP Cabling and Fanouts

Pulling Eyes

Chassis Types

Strands

Superior Customer Service // Free Technical Support // Fast Lead Times

888-568-1230

888-568-1230